Van’s Aircraft founder Richard VanGrunsven has announced changes at the company aimed at addressing “serious cash flow issues, which must be addressed quickly to ensure ongoing operations. We are confident that we can work through this situation, but some changes are required,” he says. Van’s posted an extensive explanation of the situation in addition to the video featuring founder VanGrunsven. (You can read it here.)

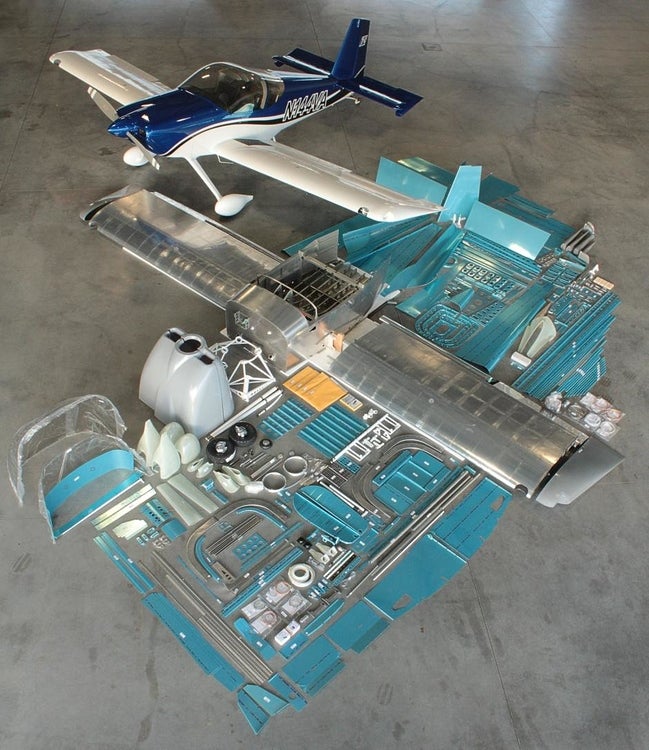

Van’s current challenges result from “a combination of significant events over a relatively short period of time [that have] increased costs, doubled normal inventory levels, slowed deliveries, and strained our cash flow to the breaking point,” the company says. It cites increases in manufacturing still evident from the COVID slowdown, an issue with primer used by a subcontractor in quickbuild components and the most recent problems with laser-cut parts, which were a response to help increase production capacity at a time when Van’s was experiencing historically high demand. Builders discovered that the laser-cut parts tended to crack during the dimpling process. “Although our testing proved that laser-cut parts are functionally equivalent to punched parts, belief among many builders is that they are unsuitable for use,” the company says. “This has resulted in an unmanageable number of requests to replace laser-cut parts and cancel orders. More than 1800 customers are currently affected by this issue, some of whom have received more than one kit.”

As part of the announcement, Van’s said that “starting today through mid-November, Van’s will be focused on assessing the internal changes necessary to address these issues. This means some of the typical day-to-day operations at Van’s will be affected while our team develops plans to correct the problem.”

Those changes include streamlining the company’s efforts to focus on replacing laser-cut parts for existing builders and reassessing its manufacturing processes. “During this period, shipments will be delayed, kit orders will not be processed, and refunds will not be issued,” the company says. “We will be unable to conduct factory tours and demo flights. We are adjusting our daily operating hours. Starting Monday, October 30th we will be open from 8:00 a.m. to 4:00 p.m. Pacific Time each business day. Our builder technical support hours will shift to 8:00 to 9:30 a.m. and 3:00 to 4:00 p.m. each business day. This is a permanent change.”

In the background, Van’s has “assembled a small team of experienced advisors to assist us” from Hamstreet & Associates, a Portland, Oregon-based firm that “leads troubled companies through financial and operational crises, and delivers results.” That team includes interim CEO, Mikael Via, who had served Glasair Aviation in the early 2000s and developed the Two Weeks to Taxi builder-assist program. Hamstreet is expected to provide financial expertise as well as other interim officers to help Van’s move forward.

Builders and potential Van’s customers are likely to wonder about pricing and availability in the future. “Van’s Aircraft faces several challenges that require us to take time between now and mid-November to perform an internal assessment of our inventory, production, and shipping capabilities as well as overall operating efficiencies,” Van’s says. “During this time, we will be evaluating all reasonable means of satisfying builder concerns regarding laser-cut parts. At the same time, we will be reviewing the costing of our parts and kits.”

Van’s is expected to issue updates via its website in the near future.

Editor’s Note: This article first appeared on KITPLANES.