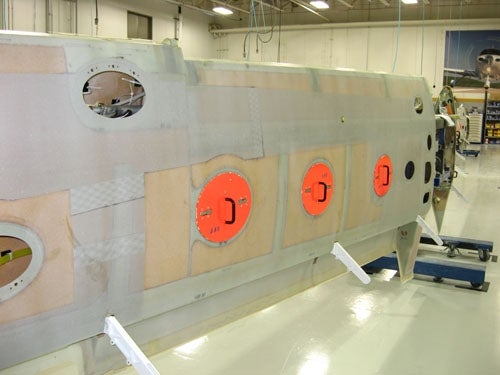

**A wing section of an SR22 cures in the autoclave. As you can see, the parts are built with additional material that is used for any number of manufacturing purposes, but they're mostly for attaching to jigs for assembly down the line a ways. Photos By: Robert Goyer