FlightSafety’s highly realistic level-D Pilatus PC-12 simulators are terrific platforms for learning the elevated complexities associated with flying turboprops. FlightSafety

It was a beautiful day. Light winds. Clear skies. Towering, snowcapped Rocky Mountain peaks surrounded the 9,000-foot runway at Eagle, Colorado, from which I was about to depart. I was at the controls of a Pilatus PC-12, a sizable single-engine turboprop built to carry thousands of pounds of people or gear. Today we were light. Just two people and full tanks.

I put the condition lever in flight idle and pushed the power control lever forward. The engine gauges gave me the green light to go. The heavy turboprop spryly rolled down the runway and lifted off. Gauges still in the green, positive rate of climb, gear up.

With a nice climb rate, we were approaching the snowline of the tall peaks when suddenly — bang! A catastrophic engine failure. As soon as I regained my composure, I pulled the condition lever aft to feather the prop and started turning back toward the runway. I did my best to target the optimal spot on the angle-of-attack indicator to maintain the maximum amount of glide. Gear down, flaps down. I was almost at the approach end of Runway 25 but realized I would not make it to the concrete. My pulse rate crept higher. My palms started sweating. Brace for impact …

Fortunately, I was safely strapped into a full-motion simulator at FlightSafety International rather than an actual PC-12 in the Colorado mountains. The realism was impressive, and I learned a tough lesson. When things go wrong in a turboprop, you need to know your emergency procedures like the back of your hand in order to maximize your chances of a safe outcome.

Thankfully, engine failures in turboprops are quite rare. Most turboprops sold today, the PC-12 included, are powered by the Pratt & Whitney Canada PT6, one of the most dependable engines in the world. However, reliability can give pilots a false sense of security. No airplane is failureproof.

In my decade and a half of flying airplanes, I've had a chance to fly several single-engine turboprops: the Cessna 208 Caravan, the Daher-Socata TBM 700, the Epic and the Lancair Evolution. Lacking any formal training, I felt pretty confident that I could grab a checklist, successfully start up one of these airplanes, steal it Airplane Repo-style, and safely get it to where I wanted to go (provided all systems remained operational).

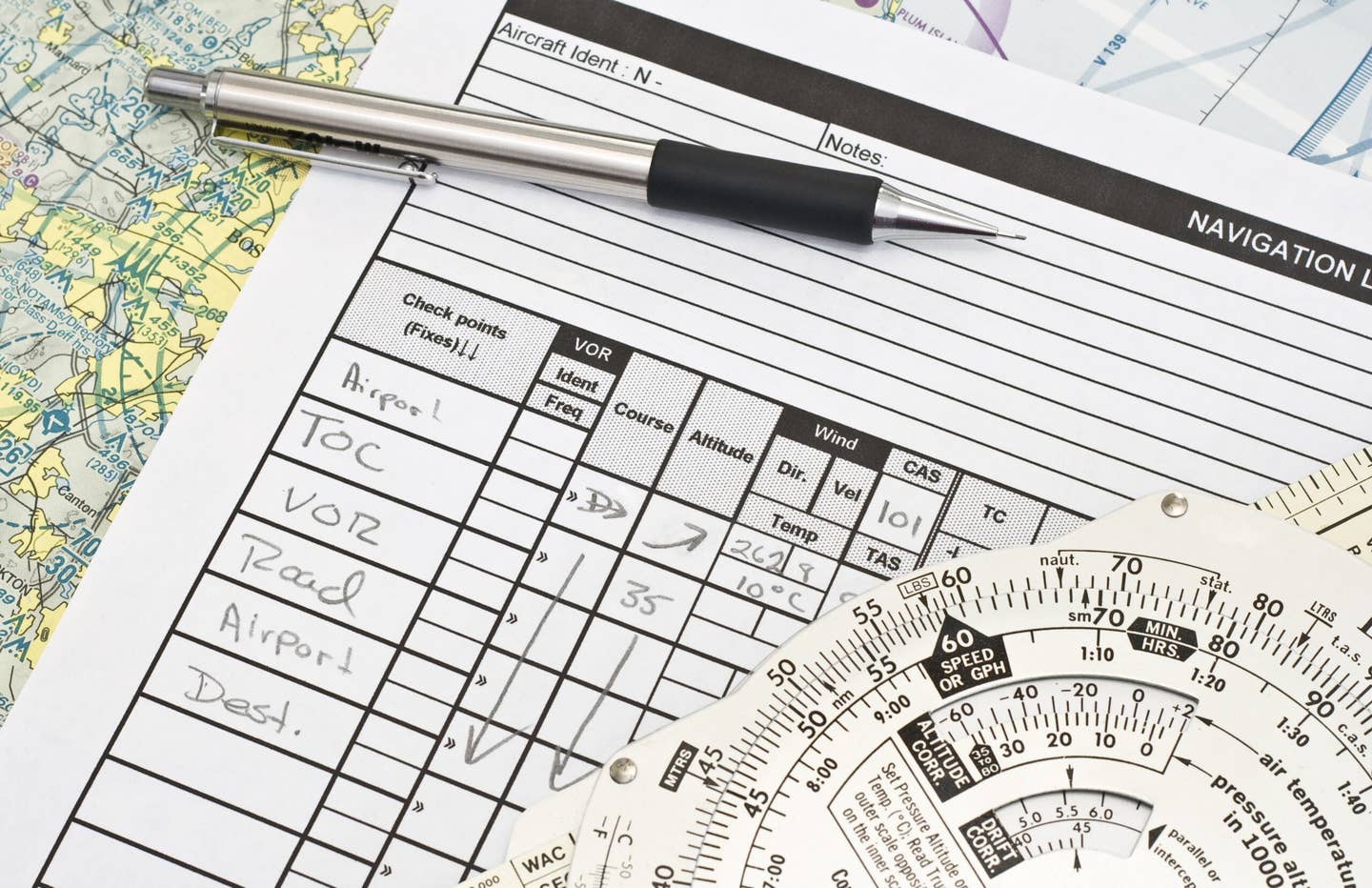

Normal turboprop operations are, for the most part, at least as easy as those of piston-powered airplanes. However, you'll notice that the power quadrant in a turboprop is quite different. Rather than throttle, prop and mixture controls, there is a power control lever (PCL), condition lever (CL) and manual override lever (MOR).

On the ground, the PCL controls the propeller and engine power. This is also referred to as beta mode. In beta, the PCL can reverse the propeller pitch, allowing you to slow the airplane without using brakes. In flight mode, the PCL essentially acts like a throttle while the propeller is controlled by the governor.

The CL has three positions: cutoff/feather kills the engine and feathers the propeller, ground idle is used for start and ground operations, and flight idle is used (you guessed it) during flight. To prevent an inadvertent shutdown, the CL in the PC-12 has a safety latch that must be moved, and the CL must be lifted to cut off the engine and feather the prop. It definitely takes a bit of practice to get right, and in a true emergency, such as an engine fire, you'd want it all to be second nature.

Finally, the MOR is essentially a secondary throttle used in case the PCL fails or in case of a pneumatic failure of the fuel control, indicated by a loss of fuel pressure and partial loss of power. So unless there is a problem, you would never have to use the MOR.

You can pretty much manipulate the PCL as aggressively as you want without having to worry about damaging the engine as long as the gauges remain in the green. While heavier than light GA airplanes, the turboprops I've flown have nimble controls and can be hand-flown without the need for massive muscles, with the help of trim, of course. But these complex airplanes are generally flown using the autopilot, and often the aspect that requires the most training is the avionics systems.

Single-engine turboprops, even the highly sophisticated Pilatus PC-12, all have gross weights below 12,500 pounds and, as such, fall under the category of airplanes that don't require a type rating. But turboprops are faster, fly higher and have more advanced systems than piston airplanes, all of which requires more competence obtained only through specialized transition flight training.

As in many aviation scenarios, rather than the FAA requiring specific type training, the insurance companies have become the safety regulators. To obtain insurance for a turboprop, pilots who transition from piston-powered airplanes are generally required to have an instrument rating and at least a few hundred hours of pilot-in-command time, pass an approved transition training course, and receive as much as 50 hours of dual instruction in the type of airplane to be flown, says Jan D'Angelo, former vice president of Chartis Aerospace (now AIG).

Wow. That seems like a lot of training for an airplane simple enough that I could successfully steal it, I thought to myself. And unfortunately, that is the attitude many pilots have, according to David Robinson, the founder of Elite Pilot Services, which provides training in the Epic and the Lancair Evolution.

"There is significantly more to being qualified to fly the airplane than a smooth landing," Robinson says. Pilots can be pushy and want to be done with the training before they are really ready. But as professional training providers, instructors at Elite Pilot Services will not sign pilots off until they are fully prepared. "We basically require that a student can fly to check-ride accuracy without depending on the autopilot as a crutch," Robinson says.

While there are companies, such as Elite Pilot Services, that conduct training directly in airplanes, companies such as FlightSafety and SimCom train using highly sophisticated simulators — so sophisticated, in fact, that they often cost as much as or even more to build than an actual airplane. The simulators also require regular maintenance, just like an airplane. At FlightSafety, a technician inspects the level-D sims once every 24 hours, says John Patterson, FlightSafety's program manager for the PC-12.

Most pilots walking through the doors of FlightSafety and SimCom are there to get either a type rating or maintain currency in an aircraft that requires one — in most cases, jet- engine-powered airplanes and helicopters. But these training facilities also offer sim training in twin turboprops such as Beechcraft King Airs and the Piaggio Avanti, and singles such as the TBM and PC-12.

As mentioned before, the actual hands-on operation of a turboprop is relatively simple. Where the training really counts is if and when something doesn't go as planned. With more sophisticated systems, greater speed and higher altitudes, things can go really, really bad — really, really fast.

For most systems failures, adequate training has the potential to save your life. There have been several pressurization-related fatal accidents in the past few years in various types of turboprops. In some of these cases, quick action by the pilot may have mitigated the situation.

For example, in 2014 a TBM 900 crashed in the water near Jamaica, killing a husband and wife after the pilot's increasingly incoherent communication with ATC seemed to indicate that he was becoming hypoxic. It didn't take long before the pilot became completely incapacitated while cruising on autopilot at 25,000 feet. While it is impossible to know exactly what happened, it is likely that swiftly donning an oxygen mask or making an emergency descent may have saved the pilot and his wife's lives.

While you would have to go to an altitude chamber to experience firsthand how quickly hypoxia sets in at altitudes where turboprops are most efficient, a full-motion simulator allows most failures to be practiced in a realistic but safe environment. FlightSafety introduced the first level-D PC-12 simulator in the world in 2013 with the PC-12NG (the latest version of the airplane), Patterson says. Today, the facility has two PC-12 sims, having added the legacy PC-12/47 in late 2014.

The simulators allow FlightSafety's instructors to put their customers through real-life scenarios that you wouldn't want to expose yourself to in an airplane. And some critical failures that must be mitigated immediately, such as runaway trim, are impossible to simulate effectively in the airplane.

FlightSafety's initial training course for the PC-12 includes 40 hours of ground instruction, five hours in a nonmotion simulator and 10-12 hours in the level-D sim. Recurrent trainees spend 16 hours in the classroom and five to six hours in the full-motion sim. To get a taste of what the training was all about, I went to Dallas to check out the course.

Since I was not actually going to work as a professional PC-12 pilot, I was placed in a recurrent class to see how the program is conducted. My instructor was Tom Evans, who has been teaching pilots to fly the Pilatus since 1994 when the airplane was first introduced in the United States.

Evans' seemingly limitless knowledge of the airplane and its systems was effectively presented through FlightSafety's sophisticated "smart boards," which allowed him to quickly zoom in on certain areas — for example, a particular area on the instrument panel — to make it easier to follow along. Videos were also incorporated. In addition to two massive screens at the front of the classroom, an additional smart board was used on a sidewall where Evans mostly displayed checklists.

I was paired up with a couple of Brazilian pilots who fly PC-12s for Azul Airlines. Despite the fact that the two had been flying the Pilatus for a while, they had not attended FlightSafety's course before. While they exhibited an excellent level of knowledge of the systems of the airplane, there is no doubt that they benefited from the program and Evans' vast knowledge.

For example, in the PC-12 there is a button called "trim interrupt" located prominently above the throttle quadrant. When pushed, this button immediately disables the trim functions. "Why on earth would you want to do that?" you might ask.

The PC-12 is a 10,495-pound airplane at max gross, and pitch control is performed through a large elevator. If you were to suddenly experience a runaway trim scenario and allow the trim to bring the elevator to either full-up or full-down deflection, Evans says it is unlikely that you would be able to maintain control of the airplane.

I observed a simulator session with my classmates, who displayed excellent flying and CRM skills in the PC-12. But when Evans presented a runaway trim scenario, the pilot acting as captain was all over the cockpit desperately trying to find the right circuit breakers, some of which are on the copilot's side. All he needed to do was push the trim- interrupt button to stop the continued deflection, then move to the checklists and potentially deactivate the system with the circuit breakers.

The experience really brought home the importance of training and practice. We had discussed the trim-interrupt feature extensively in the classroom, but when the scenario presented itself in the simulator, it was not in the forefront of the pilot's mind until he had actually practiced it a few times.

Another intense scenario that would be impossible to duplicate with as much realism in an airplane was when the Brazilians were presented with smoke in the cockpit. They handled this task with perfection as they quickly donned their oxygen masks before attacking the emergency mitigation.

With as much as 1,200 shp delivered by the P&WC PT6A-57 engine, the stick shaker/pusher is mandatory equipment. With all that power, there is potential for a torque roll (the airplane wants to roll left as a reaction to the propeller spinning right — something that is perfectly OK to do in an aerobatic airplane, but not in a sophisticated turboprop) in a high power, high angle-of-attack scenario. Experiencing the stick shaker/pusher and how to manage high angles of attack is definitely more comfortable to do in the safe environment of a simulator.

I tested the stick shaker/pusher during one of my simulator flights, which I flew with Patterson, and it was a valuable experience. I could see how, if I had never been exposed to the feeling of the shaker or pusher before, it could startle me, wasting valuable time I could better spend mitigating the problem.

Patterson also tested me with an engine failure prior to lift off, and we flew in and out of Aspen, Colorado — a notoriously challenging airport nestled in a boxed canyon in the Rocky Mountains. To top things off and show off some more of the level-D sim's capability, Patterson put me in a thunderstorm, and boy was it an intense, rocky ride. These were scenarios that could be classified as fun in a full-motion sim but certainly not in a real airplane.

Attempting the climb out of Eagle once again, Patterson gave me the exact same engine failure scenario that caused me to crash earlier in the session. But this time I knew what to do. I referenced the angle of attack and kept the speed tape in the right spot, and made a sharp turn for the runway while feathering the prop, lowering the gear and putting in landing flaps. My procedures were so efficient that I had to slip the Pilatus to get it on the ground. My landing may not have been a greaser, but if it was a real PC-12 I think the airplane would have been in great shape.

PC-12 Pro

While at FlightSafety, I was fortunate to be placed in the classroom with Tom Evans, one of the most experienced Pilatus PC-12 instructors in the world. Evans first learned about the PC-12 in 1989 in an article in Flying called "A Swiss to Watch." He was immediately drawn to the airplane, which at that point was only in the proof-of-concept stage.

In 1991, Evans was teaching in various turboprop airplanes at SimCom when Pilatus approached the company to become the factory-authorized training facility. He jumped at the opportunity and made a request to become a PC-12 instructor. Evans was trained in the prototype in Stans, Switzerland, in 1994 while the first production airplane was being built there. at that time, all training was conducted in the actual PC-12. "Twenty-one years later, I still love the airplane," Evans says.

Flying is part of Evans' DNA. His father and grandfather were both pilots. He soloed at the age of 16, got his license at 17, and then became an instructor. While Evans had a stint doing corporate flying, his passion lies in instruction. "No matter what I was flying, I was always teaching someone something," he says.

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox