Knowing What’s ‘Normal’ Is a Big Part of Preflight Inspections

The learner pilot–with checklist in hand—should never be afraid to ask questions.

[Shutterstock]

Anytime you learn a new skill, there will be a phase where you don't know what you don't know. Flying is a prime example of this. Expect the first manifestation to be when you are learning to do a preflight inspection of the aircraft. You may find yourself asking questions like "Is that normal?" and "Is it supposed to be like that?" as you look at the aircraft. These questions should be asked as they are part of the process.

What Is Normal?

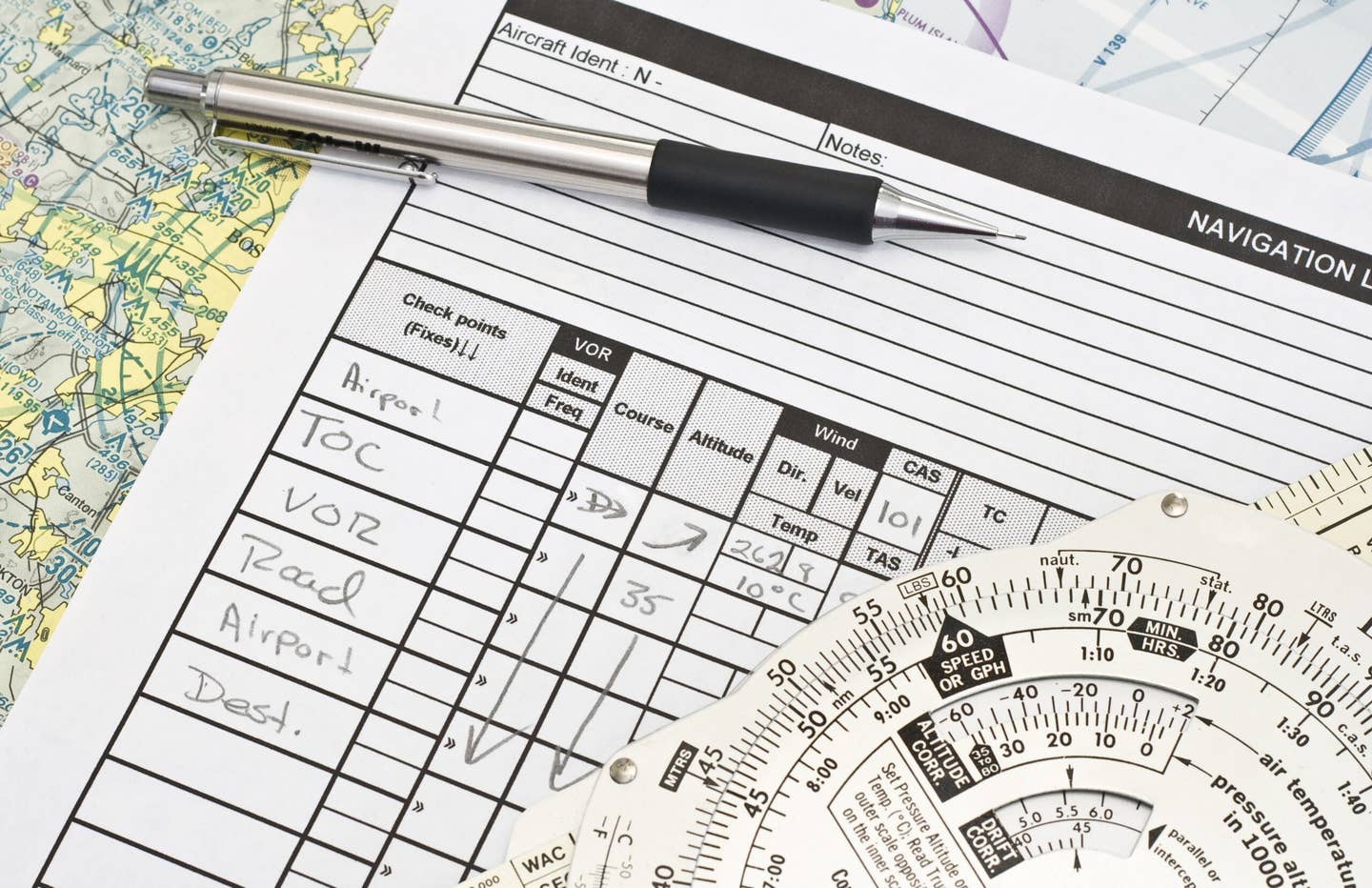

On your first preflight inspection, your instructor will likely teach you how to perform it, checklist in hand. It doesn't matter how long you've been flying, use the checklist. In addition to providing a logical flow to the inspection, it often offers metrics for normal and safe operations, such as "minimum oil level 5 quarts".

It is OK, in fact encouraged, to be extra cautious when it comes to potential discrepancies found during the preflight inspection. If you have never flown a particular airplane before, and it is your usual slightly beat-up flight school rental, you will probably find things that give you pause. For example, that crack on the plastic wingtip that terminates in a drilled hole. A good instructor will use this as an opportunity to explain stop-gap drilling.

- READ MORE: Make the Most of the Checklist

Sometimes you will find more than one thing on an airplane that concerns you or have a question about, but you're so focused on the inspection you may forget that you had a question. This is common. During my student days, I got into the habit of leaving the left wing tied down as a reminder to myself that I had a question for the instructor. Pretty soon my instructors were trained to recognize this symbol. Today my learners use this technique.

There may be a situation where the CFI calls a mechanic for their opinion. The first time I did this was when my learner found a nick in the propeller—a piece of sharp metal sticking up. The mechanic came out and inspected the propeller, then used a file to dress the crack and blade. It was an excellent teachable moment for both the learner and myself, and it taught the learner not to be intimidated by mechanics.

I don't remember a single time a mechanic became cross with me for asking their opinion on something. One mechanic explained it to me by saying, "These are our airplanes too," and they'd rather have it be a nonissue than something that creates a problem in the air.

The best flight schools are the ones where the CFIs and mechanics work as a team. This begins by respecting each other's space and skill sets. I rather enjoyed being called upon to assist the mechanics when they have a task like swinging a compass or taking them up on a diagnostic flight.

If the school is Part 141 only mechanics can touch the aircraft. I've been told that even the replacement of a screw in the cowling by someone other than a mechanic can result in sanctions from the FAA. Under Part 61, this apparently isn't the case, but you should never borrow a tool without permission. The mechanics I know keep their toolboxes very well organized. A missing tool—or one not put back in the right place and therefore perceived as missing can make a mechanic wonder if they left it in an aircraft—is not a good thing.

I can't borrow tools without permission. I just can't. One of the worst punishments I received as a child was when I borrowed my father's hand tools without permission. I was 7, and let's just say learning took place.

One mechanic I worked with said I could borrow his tools, but he asked that I return them on top of his toolbox with a note indicating that it had been borrowed and now returned. I respected this.

It is extremely disturbing to find a tool where one is not supposed to be—on the ramp, on the runway, or in the airplane. A former colleague found an Allen wrench on the battery of Cessna 172 during a preflight inspection and, for reasons that still escape me, thought it had been put there for him to find as some sort of joke. I am still not sure why he thought it was about him, and I was horrified. I still don't get how leaving a tool in an engine could be a joke.

That being said, I do use colorful plastic toy frogs on the exterior of the aircraft and in the cockpit to check a learner's preflight inspection and start scenario dialogues. For example, a frog on the fuel selector valve might mean the placard of the valve is missing. Is the aircraft still airworthy? Learning takes place. I always collect the frogs after the inspection.

Most often, though, the learner's discoveries of potential issues during the preflight inspection are not serious but are quirks of the airplane. It is often a relief to learn that the dent you found along the empennage has been there for months, and it is important that the instructor validate the learner's observation, especially when it's tied to their use of the checklist. During the run-up, the learner observed a rough-running magneto. There was too much of a discrepancy between the magnetos, per the checklist, for a safe flight, and I admit I was proud of my learner when he stated this. That was the day he learned how to clear a bad magneto.

When You Find Damage

Sometimes learners are reluctant to report damage they find for fear they will be blamed for it and billed for repairs. I witnessed a pre-solo learner near tears when she found a wingtip light hanging by a wire. Her CFI called me over to take a look. It was obvious the wingtip had collided with something.

"There's no way you did this," the CFI told her. “Something hit it.”

A little bit of sleuthing revealed that the line worker pulling the aircraft to the fuel pump had misjudged the distance between the aircraft wing and fence line. The line worker said he thought he felt it drag, but then it came loose so he didn't think anything of it.

As it was a daytime flight, the lesson took place. However, a placard was inserted and a note made on the dispatch binder advising renters that the aircraft was for daytime VFR only. The lesson for the day included how to report a squawk. At this school the form included what aircraft, who found the squawk, when, were you solo or with a CFI, phase of flight, and action taken, as in which mechanic or administrator did you notify. Sounds like a lot to do, but, as I was told, there was precedence when squawks were verbally reported to the dispatcher, who wasn't a pilot and often didn't understand the issue and its impact on airworthiness. The detailed squawk report addressed this.

Squawks Don't Just Disappear

Just because something is squawked doesn't mean it gets addressed. If it doesn't impact airworthiness or safety of flight, it may be deferred until the next inspection. However, be wary of a school that encourages instructors and renters to fly aircraft with known squawks, such as oil leaks or flat spots on tires with cords showing. Big red flag: If the local designated pilot examiners are reluctant to fly in those aircraft, take note.

If you feel uneasy about the mechanical condition of an airplane, remember you are not being forced to fly it. That apprehension could be from a lack of experience, or you could have a valid concern. It's always best to err on the side of caution.

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox