First Officer Bruce Wilmer

(January 2012) After I had introduced myself to Eric, the number one flight attendant for our Miami turnaround from JFK, he reluctantly conveyed some of the more annoying events from the same trip a day earlier. I told Eric that the copilot and I were commuters and that our primary purpose was to end the day safely and on time. No drama would be allowed. Then I broke my own rule.

First on the drama list was an overbooking issue. A friendly discussion with the gate agent as she escorted me down the jet bridge indicated that her math and the reservation computer’s math didn’t agree. Our flight was overbooked by more than her calculations had determined. I discovered later that part of the problem was the fact that maintenance had declared two seats inoperative because of electrical issues. The other problem would manifest itself in the form of six soon-to-be-upset passengers. More on that later.

I walked down the jet bridge stairs and onto the ramp. It was the copilot’s leg to Miami and I had offered to conduct the walk-around inspection. Captains should not perform walk-arounds because stuff just seems to happen. True to form, I discovered an oil leak underneath the right engine cowl nearest the IDG (integrated drive generator) access panel. A leak is not typical of Rolls-Royce engines. Judging by the leak location, I was hoping that it was a simple overservicing issue, analogous to overfilling the oil in a car’s engine.

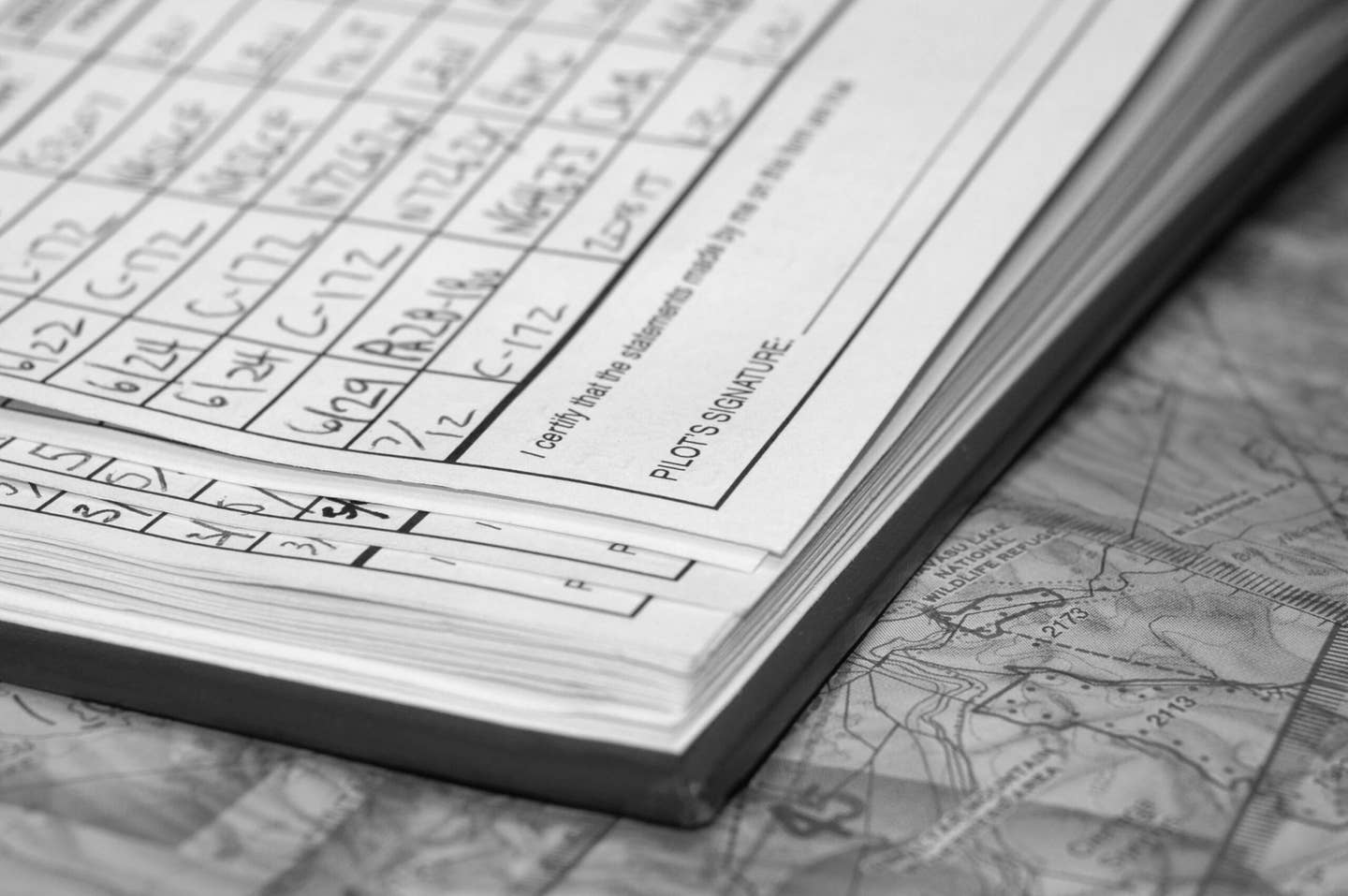

Upon my return to the cockpit, I informed my copilot, Bruce Wilmer, of the problem. In a relaxed tone, he conveyed the information to maintenance via our company radio frequency. After nearly 20 years with the airline, Bruce’s seniority had allowed him the opportunity to upgrade to captain on the 737. He had been a captain for seven months and then the rug had been pulled out from underneath him. He was eager to put four stripes back on but was still grateful to have the big-iron experience. In any case, an oil leak was not going to raise his blood pressure.

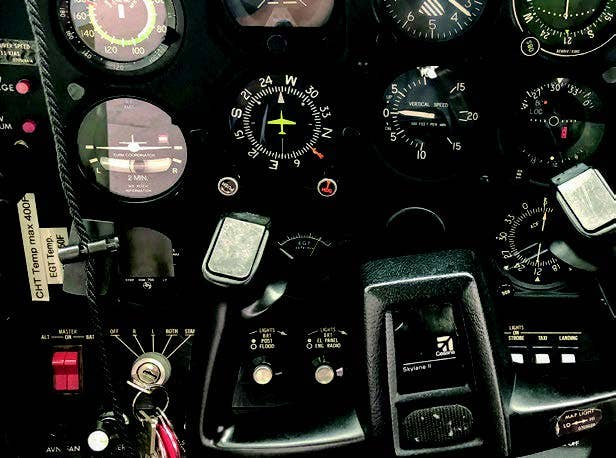

In the meantime, we began our before-starting-engines checklist.

Interestingly enough, my checklist responses were accompanied by the curious vocals of a barking dog. Thinking that the barking was originating from the forward cargo compartment below, we completed all of the required items undaunted by the distraction. It took only another brief moment to realize that the yapping was actually occurring on board in the first-class cabin. Eric’s consternation as he stepped into the cockpit confirmed this fact.

Fortunately, the dog owner was embarrassed and had already begun step one of the bark reduction plan. A Benadryl had been administered. Step two of the plan was the owner’s request to keep a reassuring hand on the dog’s head through the open flap of the portable kennel. Judging by the fact that the dog never uttered a peep for the remainder of the flight, I’d place bets that step one was the more effective.

With the animal issue resolved, we moved on to the next drama. The overbooking had now reared its ugly head. Six passengers who had been bumped from a previous Miami flight were given seats on our flight. But that presented a problem. Passengers who were on a voluntary oversold status for our flight technically had priority. If they were bumped, my airline would have to buy them off and give them guaranteed seats on a later flight. Unfortunately, the decision was not made until after the party of six that had been involuntarily bumped earlier was already comfortably seated. With tears in some of their eyes, they were gently removed by an agonized gate agent. In the long run, the decision may very well have cost my company more money in the form of ill will. But that wasn’t my call.

At some point during the course of events on board, a mechanic had arrived to diagnose the oil leak. We were not aware of his presence until he chimed us on the interphone from down below on the ramp. Although he felt relatively confident that the problem could be attributed to overservicing, the mechanic anticipated the need to start the engine as verification that the leak source wasn’t elsewhere. He would advise us when the start was required. Scheduled departure time was almost upon us.

On cue, Eric re-entered the cockpit. Apparently catering had eliminated the enchiladas from the enchilada plates of four first-class passengers. Bruce initiated another company radio call for this crisis.

A few minutes later we began the first of three engine starts as the mechanics continued the troubleshooting process. The engine starts forced me to rattle my brain in order to recall limitation numbers. What was the starter duty cycle? Oh, hell … I reached into my flight bag and pulled out the operating manual. Better to admit memory defeat than break something expensive.

After the third and last engine start, the mechanics were satisfied. They would be on board in a few minutes to make the appropriate entries in the maintenance logbook. And then we were informed of another catering crisis.

One of our first-class passengers claimed to have requested a kosher meal. Per procedure, the reservationist would have informed him that our particular domestic flight did not offer that meal option. En route we would learn that the passenger had provided his own kosher cuisine anyway. Did he actually consider airline kosher to be superior?

A mere 45 minutes late, we pushed back from the gate. The drama continued, if only for a brief moment during the course of our engine start. An EICAS (engine instrument and crew alerting system) status message annunciated, indicating that the No. 2 center hydraulic demand pump had issues. Bruce and I exchanged incredulous expressions. It was a cold day. Within 30 seconds the message disappeared. Small favors …

In regard to the cold day, our light weight of 419,000 pounds allowed the 777 to leap into the air with Space Shuttle performance. Two engines, each with 90,000 pounds of thrust, made Bernoulli’s Principle easy.

Our flight plan was computed at 0.85 Mach, not an atypical speed. The airplane always seems to enjoy that number. Long-range fuel efficiency is usually at or near the airplane’s peak.

Unfortunately, a company 777 flight returning from London ahead and at our altitude of FL 400 wasn’t following suit. The flight was asked by the Center controller if it could increase the speed to 0.85 Mach. A seemingly reluctant voice agreed.

Upon our arrival, drama greeted us again. The agent attempted to maneuver the jet bridge to the nonstandard 1L door, the most forward door on the left side.

Normally, the 2L door is utilized in Miami. The 2L door is nearest the left engine. Procedure requires that another agent be present for the maneuvering process as a safety measure to avoid striking the engine. The second agent was not available. The only option remaining was to attempt an awkward repositioning toward door 1L. Eventually the attempt was successful.

With the flight plan paperwork reviewed for our return trip to JFK, I approached the agent at the new gate. I was warned that a small FAA team had picked our flight to observe the boarding process. That was a new one for me. No injuries occurred because of the government oversight.

Just prior to my entry into the cockpit, I observed Eric in a frustrated conversation with a noticeably tall passenger. The tall passenger turned out to be an air marshal, the same air marshal who was aboard our earlier flight from JFK. Par for the course, I had never been informed of his presence.

At the last minute, our two cockpit jumpseats became full. One occupant was a copilot for my airline. His three-day trip had fallen apart because of an earlier air-interrupt shortly after departure from JFK. His 757 had lost the left system hydraulic fluid. Unfortunately, the landing gear and flaps are part of the left system.

All worked out well, except that the trip departed JFK very late with a new airplane. The copilot and his captain were replaced on their next leg once they arrived in Miami.

And just when we thought that we were on the downside of our drama, Eric struck again. The greeting flight attendant at the 2L door stated that he was becoming dizzy because of fume inhalation. The jumpseating copilot volunteered to investigate. Upon his return, the copilot’s best guess was that the wind was blowing the APU exhaust toward the door.

Last, but not least, on the list was a cockpit that just wouldn’t cool. The rest of the cabin was comfortable, but for some unexplained reason we managed to attain a sauna temperature of 90 degrees at the pointy end. We didn’t stop wiping the sweat off our brows until FL 390. A few minutes later, I had an “ah-ha” moment. Apparently the air-conditioning packs were working overtime on the ground in MIA. The duct to the cockpit must have become blocked with condensation ice. If we had moved the temperature control knob toward full warm, the ice would have melted. Lesson learned.

The simplest part of our day was my crosswind landing in New York. If what should simply be flying the airplane instead reads like a script from a made-for-TV movie, then it probably isn’t a good day. Drama should never be included.

Send reader mail to: edit@flyingmag.com or P.O. Box 8500, Winter Park, FL 32789.

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox