It’s Time to Winterize Your Flying

If you are in a part of the world prone to snow, ice, and freezing conditions, getting from the ramp to the sky can take a little more time and planning.

All the ice and frost must be removed from the airplane before departure. [Meg Godlewski]

Flying does not stop in the winter. Despite the cold, there can be days with calm winds, unlimited visibility, and blue skies just begging to be filled with aircraft. However, if you are in a part of the world prone to snow, ice, and basic freezing conditions, getting from the ramp to the sky can take a little more time and planning.

Aircraft Stored in Hangars

If you are lucky enough to have an enclosed hangar, do your preflight inspection inside with the door closed to retain the heat. Don't open it until you are absolutely ready to take the airplane outside, then close the door quickly, as soon as it is safe to do so.

When the time comes to put the airplane back in the hangar, don't be in a rush. If this is your first winter in the hangar, you will find it helpful to put marks on the floor indicating where the tires should be placed. Paint or gaffing tape do the job. Some of the more savvy hangar owners will also put marks on the wall to indicate the wing should go no farther back than that to prevent a tail strike with the rear wall.

Pro tip: If you enlist the help of someone to help you move the aircraft, make sure they understand the concept of letting you know when the wing, tail, etc., is getting close to hitting something so you can prevent it from happening. A Piper Cub at local flight school suffered a creased wingtip because the person who normally answered phones at the flight school and was asked to "watch the wing" didn't understand this concept. So they stayed silent and watched as the pilot/owner accidentally pushed the airplane's wingtip into a wooden staircase.

Bring the Heat

When the flight school has a large fleet, and multiple flights are set to launch in the morning, there is a logistic ballet with the aircraft that go out first being kept in the hangar and the heat activated an hour or so before the client gets there. When the aircraft is pushed out of the hangar, the next one to go out is pulled inside for defrosting.

Be patient. Sometimes the doors are frozen shut. Don't try to force them. Don't be in a rush to get the ice off—and all the ice and frost must come off. Scraping ice off an airplane will damage the paint and plexiglas windows. Let it melt, instead, and wipe the slush with a squeegee or soft cloth. Budget extra time for the preflight inspection—at least 15 minutes—when aircraft defrosting is on the agenda.

Be very careful if you use a plastic bristle brush to get powdery snow off the top of an airplane. Avoid the plexiglas. Dry the aircraft with a clean, soft towel—preferably a chamois.

Pro tip: If a towel is dropped on the hangar floor or ground, it should not touch an aircraft again because there is a chance it has picked up some grit that will damage the aircraft's finish.

After the towels are used, wring them out and hang them up to dry. Some FBOs provide a laundry service that takes the used towels and replaces them with clean ones. Other FBOs buy the towels in bulk and they are one-time-use items. Dispose of the wet towels properly. You do not want to be the person who leaves a soggy, dripping-wet towel on the ground, on top of a drain, or in the sink because your mother taught you to leave used towels in the bathtub after use. Find out what the procedure is at the place you fly and follow it.

Verify the aircraft is completely dry before you move it back to the ramp so it does not refreeze.

Things to Watch For

Frozen fuel caps and the oil cap may be hard to dislodge. It helps if you can get over them (using a stepladder for a high-wing aircraft) for better leverage. Pro tip: There are specially made wrenches to remove stubborn oil caps—invest in one.

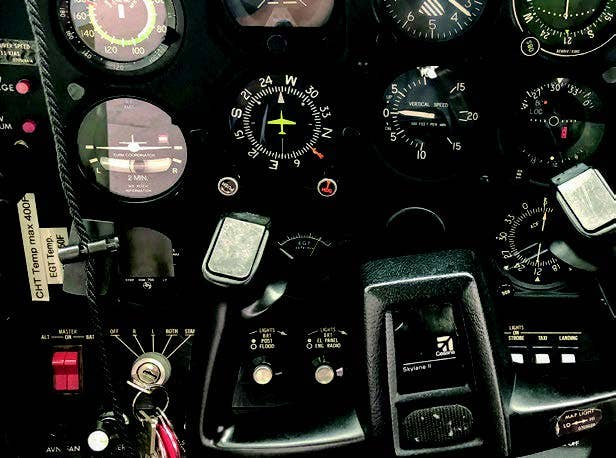

If you find ice on the glareshield or panel, there is a leak in the canopy. You may want to have the avionics shop check the radios for damage, and don't be surprised if the faces of the round-dial instruments are opaque with condensation. The only way to remove it is time and heat. Some pilots and mechanics get creative and bring in professional-grade blow dryers to expedite the moisture-clearing process. The clever CFIs use this situation as a teachable moment to review FAR 91.205 with the learner.

- READ MORE: Flying Through a Wisconsin Winter

Preheating

Even if the aircraft is kept in a hangar, it will likely need some form of preheating. This can be an electrically powered engine block heater placed inside the cowl and left on when the aircraft is not in use, or a combination of the block heater and cowl plugs and cowl cover. Some owners use oil preheaters that are activated several hours before the flight to warm the engine.

Some FBOs use butane-powered or electrically powered warm air blowers to warm up the aircraft's engine and sometimes the interior before they move an aircraft from the hangar to the ramp.

Battery Challenges

Cold weakens batteries, so some flight schools remove them from aircraft that don't fly often, keeping the batteries in the warmth of an office to preserve them. They are reinstalled before flight, so there needs to be some advance planning.

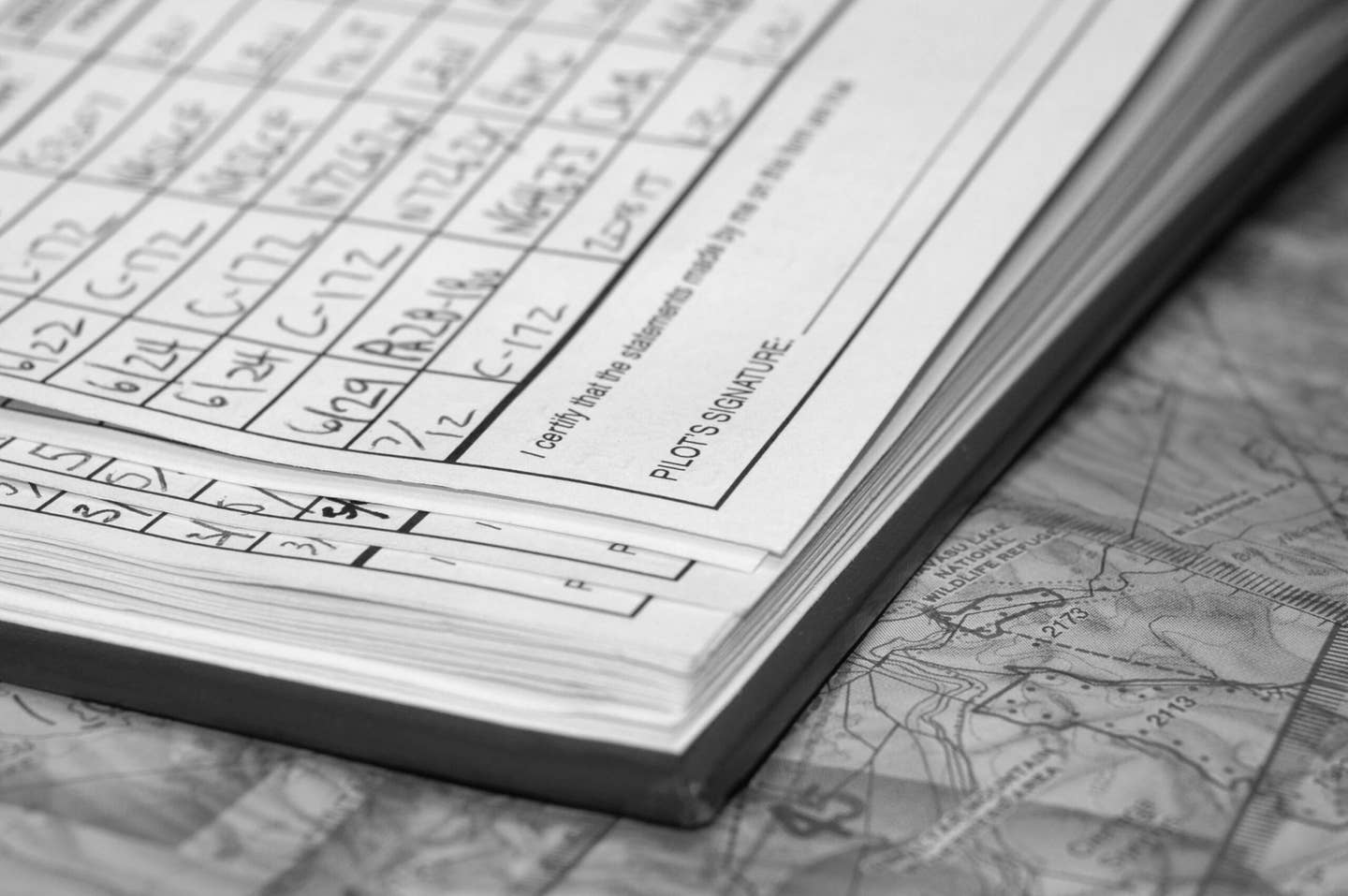

Battery conservation during the preflight inspection is also practiced. When the master switch is turned on, the electric flaps should be lowered no more than 10 degrees. Then the pilot races around the airplane to check the lights and pitot heat, stall warning if electric, then turn off the master so as not to run down the battery.

Defrosting on the Ramp

Defrosting an airplane on the ramp takes more time than in a heated hangar and is often done with a combination of sun and deicing fluid, such as isopropyl alcohol and/or hot water, followed by drying the aircraft with towels.

Deicing fluid isn't cheap, and its use may be limited to certain aircraft. Also, there is a technique for the most efficient application, so ask to be trained on that.

Using solar heat alone to defrost the airplane involves repositioning the aircraft a few times so the sun can work its magic. Remove the control lock and check to make sure the control surfaces are not frozen into place. Run your bare hand over the skin to check for ice, especially under the tail and on top of the flaps. Under certain lighting conditions—especially if the aircraft is painted white—it can be difficult to tell if there is ice on it. You find out when you attempt to lower the flaps and there is a grinding noise, then, if you are lucky, the ice breaks and the flaps come down. I have experienced a stealthy sheet of ice shaped like the flap of the Cessna 172 break off while I was dropping the flaps. It sounded like a gunshot when it broke free, and I hit the deck instinctively, much to the amusement of my CFI.

Getting from Parking to the Runway

Some nontowered airports are closed when it snows because they lack snow removal equipment. Check the notices to air missions (NOTAMs) carefully.

Airports served by air carriers or operating under Part 139 usually have snow removal plans established. The runway is usually plowed first, then the ramp, taxiways, etc. Some FBOs rely on their staff to clear the snow from in front of hangars or around their airplanes on the ramp. If this is your first winter working at an FBO in a snow-prone area, understand that it is not uncommon for the line staff and sometimes CFIs to be called into work early for this task.

Before you complain, understand that some FBO owners with aircraft parked outside will spend all day and all night at the FBO and periodically go outside to clear the snow off the tails of the aircraft to keep them from being damaged by heavy amounts.

Protect Yourself from the Cold

Know where the defroster vents are in the aircraft, and just to be safe, carry a chamois to wipe condensation from the windscreen during flight.

Don't rely on the heater in the aircraft to keep you warm. Just don't. They either come on full blast or not at all. The heat comes from outside air warmed as it passes over the engine manifold and is then ducted into the aircraft cabin. If there is a leak in the manifold, you can be poisoned by exhaust, which is tasteless, odorless, and colorless, so make sure the aircraft has a carbon monoxide (CO) detector. These can be one-time-use cardboard units that are mounted on the panel. When the CO detector turns dark, you have a problem.

The Lightspeed Delta Zulu headset has a built-in audio CO warning. This feature was introduced in fall 2022, and according to the company, has provided a potential lifesaving warning to dozens of pilots thus far.

Bonus note: If you are flying a light twin that uses a heater powered by the fuel supply, be sure to know how much fuel it is going to consume per hour (check the heater manual or aircraft POH) and plan accordingly.

Dress in layers and wear a cap, because we lose approximately 30 percent of our body heat from our heads. Be careful about how bulky your clothing is, because it is difficult to share a cockpit when both you and the CFI/copilot/learner resemble the Michelin Man. You may have to experiment to find what works for you.

CFI tip: Keep an extra jacket on hand for when the learner forgets theirs. If they are cold, they can't learn.

Protect your hands with gloves. You may only wear them during the preflight inspection, but keep them handy. While mittens are warmer, you need the dexterity gloves provide. If you don't wear gloves, be prepared for raw and chapped hands. If this happens to you, O'Keeffe's Working Hands Hand Cream is a lifesaver.

Ground Ops in the Slush

Be careful when maneuvering the aircraft on the ramp and runway. Don't expect to have any traction on ice—therefore, no brakes. While this works for floatplanes, a crosswind during takeoff or landing on an icy runway can be a disaster.

Plowed snow is usually stacked off to the side out of the way of the aircraft. Note where the piles and drains are. Plan your taxi route accordingly. Be sure to clear away the snow from drains around the hangars to avoid flooding and water intrusion.

If the Aircraft Has Covers

Remove the covers one at a time in a logical order. Shake off the snow and ice from them, and if possible, hang them in a heated hangar or other building to dry while you fly.

- READ MORE: Protecting Your Investment

Above all, have fun when you're flying—snow has a way of making everything pretty.

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox