The 225-hour commercial pilot, 55, had built his JD-2 Dyke Delta in St. Louis and, after several test flights there, took it to Safford, Arizona. Originally intended as a roadable aircraft, the JD-2 had folding wings and sufficiently springy main gear and large tires to allow it to be towed behind a car. It made the 1,400-mile trip without incident.

The airplane failed, however, to return from its first flight out of Safford. It was found the next day 10 miles from the airport, in a designated practice area, having crashed on the downhill side of a 50-foot knoll. The pilot was dead. According to the owner of the local FBO, who visited the site, the airplane must have been descending at a high rate to have cleared the top of the knoll and crashed on its descending slope. The instrument- panel G meter registered 11 Gs. The pilot’s seat and the five-point harness had been torn from their attachments.

A longtime friend of the pilot, who had helped him build the airplane and, like the pilot himself, held both commercial and A&P licenses, also visited the wreckage site. In his opinion, the airplane had collided with the ground in a 5-degree nose-down attitude, left wing slightly low, and bounced or skidded 150 feet before coming to rest. He agreed that its rate of descent must have been high.

National Transportation Safety Board investigators spoke with the designer of the JD-2, who reported that the airplane’s stall consisted of an initial forward “mushing” followed by a high sink rate and temporary loss of aircraft control. The description seemed consistent with the apparent conditions of the accident.

The NTSB concluded that the probable cause was “improper planning/decision by the owner/builder (pilot), which resulted in his failure or inability to recover from a stall/mush condition.”

After his first flight in the newly completed airplane, the pilot had told his friend that he found its stalling speed to be 160 mph. He also found it to be so nose-heavy that at low speed he had only 2 inches of nose-up stick movement available for maneuvering. To correct the nose-heaviness, he added 35 pounds of lead ballast behind the CG and replaced some of the 200 hp Lycoming’s accessories with lighter ones. These changes brought the indicated stalling speed down to 100 mph and the approach speed to 130. Watching some of the test flights, the friend noticed that the airplane tended to drop a wing just before touchdown.

Those numbers might make sense for a small jet, but the Dyke’s wing loading of less than 10 pounds per square foot would normally be associated with stall speeds of 50 mph or less. The designer reported that his prototype approached at 100 and stalled at 75; some other owners, writing online, report somewhat lower figures.

The pilot/builder must have continued to find the airplane nose-heavy, because he next added trailing edge tabs, presumably deflected upward, to the outboard trailing edges of the wings, and a T-tail. Neither of these modifications was approved, or contemplated, by the designer, whom the pilot had met and talked with at Oshkosh.

The Experimental amateur-built category of aircraft allows builders unlimited latitude in creating their own designs or modifying existing ones. Inspections before licensing the aircraft — which used to be conducted by FAA personnel, but have now largely been delegated to EAA-connected designees — are limited, or should be, to issues of soundness of construction and compliance with certain basic requirements, and do not include judgments of aerodynamic qualities, which few designees are qualified to make. Nevertheless, a customer bent on “correcting” the design is the nightmare of any plans or kit seller.

The Dyke Delta is a famous, iconic and very unusual homebuilt design dating back to the early 1960s. It is not really a delta; it is a low-aspect-ratio flying wing of more or less diamond-shaped planform, with seating for three or four. The pilot sits on the centerline, and the passengers side by side on the floor behind him.

Tailless aircraft have a narrow CG range, and so the passengers in the Dyke are near the center of lift, where their influence on the CG location is minimal. As a result, both the pilot and the power plant are ahead of the CG, and excessive weight in either or both makes the airplane nose-heavy, especially when no one is sitting in back. Normally, the largest power plant in a Dyke is a 180 hp Lycoming with a fixed-pitch prop. The accident airplane’s 200 hp engine was fitted with a constant-speed prop, which added still more weight.

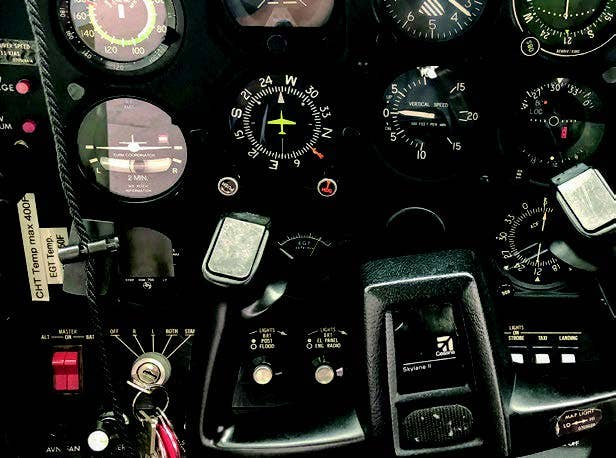

In a tailless airplane, longitudinal stability is ensured by keeping the CG ahead of the center of lift and reflexing the trailing edge of the wing — that is, curving or deflecting it upward — to produce a balancing nose-up force. Differential elevons provide pitch and roll control. The pilot evidently hoped to increase that nose-up force by adding tabs to the outboard trailing edges. The trailing edge sweeps forward just as much as the leading edge sweeps back, however, and the tips, with their short chord, contribute little to the total lift in the first place, so the tabs cannot have been very effective. The T-tail, set at an angle of negative-20 degrees to the chord line, would have had more leverage, but the accident report says nothing about its size.

The Dyke has a long nosewheel leg and sits on the ground in a markedly nose-high attitude, so that on takeoff it flies off without rotating. It is therefore incapable of taking off below its own stalling speed, and is hardly likely to have accelerated past 160 mph on the ground. The pilot’s report of a 160 mph stalling speed may have been a facetious way of saying that his airspeed indicator was wildly inaccurate and completely unreliable.

It appears that the troubles began when the builder installed a heavier engine and propeller than the designer anticipated. His subsequent effort to make the engine lighter was a step in the right direction. Not so much the ballast — generally, you’re supposed to subtract weight, not add it. The Dyke doesn’t have an extended tail, so the ballast can’t be very far aft and so can’t be very effective. Still, any port in a storm.

Any wing-only airplane is a delicate beast; when you throw in a very low aspect ratio, which implies high drag at low speed and therefore less-than-immediate stall recovery, you are getting into an area where casual changes may prove dangerous. His friend’s observation that the airplane tended to drop a wing at low speed — which could have been due to a small asymmetry in the added tabs — suggests that it might have rolled uncontrollably during a stall and then lost altitude rapidly.

The Dyke has been around for more than 50 years. According to one online source, about 50 Dyke Deltas have been built, and fewer than a dozen are still flying. The airplane is a bit of a freak, but this accident is the only fatal one I find in the NTSB records, and the only one that apparently involved loss of control in flight rather than mechanical failure. The Dyke, like any other homebuilt, is apparently safe enough — if you stick to the plans.

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox