** As you lean the mixture, cylinders get hotter.

But they cool rapidly on the lean side of

peak EGT.**

An incensed reader, reacting to my parenthetical remark "Making Range," Technicalities, August 2012 that, contrary to widespread belief, a leaner-than-peak-EGT mixture reduces cylinder head temperatures, wrote:

_Maybe I am missing something, but it is against the laws of physics that a leaner mixture can run cooler, as the more dense the mixture, the cooler the chamber is, thus EGT rises when lean’d, so how can this be “contrary to widespread belief”? _

He adds an apocalyptic postscript:

P.S. We all know that lean mixtures can melt valves, crack seats, melt heads, destroy plugs, crack cylinders, burn valves, cause premature destruction of all metals the “hot spot” touches!! Now some of Peter’s readers will think lean is good — what about the idiot that overleans cuz Pete says is good cooler and “OK”!! Liability?

Since he doubts, I will call my impassioned correspondent Thomas. His views are those of a great many pilots, though his Shakespearean spelling (“lean’d”) endears him to me above most others.

The subject of mixture is not very complicated in principle; where it gets complicated is in practice. Let’s start — since dueling Thomas has chosen that heaviest of weapons, the Laws of Physics — with the physics.

In reciprocating engines, heat is generated by burning a fuel composed of molecules called hydrocarbons, which consist of hydrogen and carbon atoms in various combinations. What we call burning is a rapid chemical reaction in which oxygen molecules dismantle hydrocarbons and reassemble their components into carbon dioxide (one carbon and two oxygens) and water (one oxygen and two hydrogens). Energy, in the form of heat, is released in the process. The temperature of everything in the cylinder rises, including that of the other gases, like nitrogen, that compose nearly 80 percent of atmospheric air and do not take an active part in the combustion process. The gases expand, pushing the piston down, and off we go.

If you took high school chemistry, you may recall, if nothing else, that chemical reactions involve atoms matching up in certain definite numerical relationships, like dancers at a prom — at least the old type of one-male-to-one-female prom. If more oxygen atoms are present than there are hydrogen and carbon atoms for them to link up with, they remain, at the end, wallflowers. Likewise the hydrogens and the carbons. When the amounts of oxygen and hydrocarbon molecules present are perfectly matched, the mixture is called “stoichiometric” — stow-icky-oh-MET-rick. The stoichiometric ratio of air and avgas is about 15.2 pounds of air to one pound of avgas — which may be visualized as a 6-foot cube of air and a 4-inch cube of fuel.

That is the idealized picture. Reality is more complicated. Because both fuel and air contain a potpourri of components, a lot of other chemistry goes on in the high-temperature environment of the cylinder. Burning, furthermore, is not a pure and instantaneous process; it is affected by spark timing and flame propagation rate and quenching by the relatively cool cylinder walls and various other things. Nevertheless, a few general statements about mixture and engine health can be made. They are not the ones offered by Thomas.

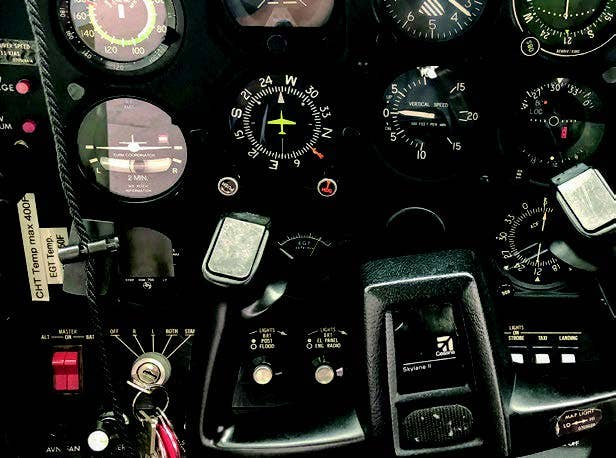

We can’t weigh the air and fuel entering the cylinder while we’re flying, so we measure the mixture by the exhaust gas temperature (EGT) instead. You would expect that an excess of fuel or air would dilute the heat released by combustion and thereby lower the EGT. So it does. You might also assume that the highest power output and the highest cylinder head temperature (CHT) would coincide with the highest EGT, but there you would be wrong, because of some of the aforementioned complications of combustion. Different engines will have slightly different characteristics, but a typical Lycoming chart shows that power output peaks when EGT is about 125 degrees Fahrenheit on the rich side of peak (ROP). Cylinder temperature is highest at 25 degrees ROP. Efficiency — power produced per pound of fuel burned — is greatest at about 40 degrees on the lean side of peak (LOP). These figures vary somewhat with power setting and among different engines, but the general trends remain the same.

That Lycoming chart and others like it use the fuel-air ratio as their baseline. Their perspective is that of a researcher, not a pilot. Since pilots can measure that ratio only by EGT, EGT should be our baseline. With this in mind, I have redrawn the chart (page 84).

Mixture, measured in degrees Fahrenheit below peak EGT, grows leaner from left to right. The colored lines show how fuel flow, speed and cylinder head temperature change as the mixture becomes leaner. These changes are expressed as ratios to the values at peak EGT; that is why all the lines converge at the peak EGT point. For example, at

100 degrees Fahrenheit on the rich side of peak EGT, fuel consumption is 20 percent greater than at peak EGT. That is, if you burn 15 gallons an hour at peak EGT, you will burn 18 at 100 degrees ROP.

In a graph like this, the steeper the slope of a line is, the larger and more rapid is its response to the controlling variable — in this case, EGT. Lines that are relatively flat reveal small, probably inconsequential variations. You can see at a glance that fuel consumption (blue) is very sensitive to mixture. Speed (yellow) varies little on the rich side of peak, but falls off more rapidly on the lean side.

The most interesting line, in the context of Thomas’ prediction of a general deflagration within the engine, is that of CHT (red). CHT rises gradually as the mixture is leaned, hits its maximum a little on the rich side of peak and drops thereafter. It drops much more steeply on the lean side than it rises on the rich side. Many pilots, trained to shun an overly lean mixture, would find this hard to believe, but pilots who regularly fly on the lean side of peak know it well: Cylinder heads run noticeably cooler LOP.

So how did Thomas, and others like him, get the idea that LOP operation would fry an engine?

I suppose it may be due to a number of factors. One is historical. Much of the science of high-performance aviation recips was developed before and during World War II and applied to highly supercharged engines whose design goal was a high power-to-weight ratio. These engines were difficult to cool and prone to detonation at high power but could be protected by running rich — in effect, cooling with fuel. There arose, consequently, an association of lean mixtures with possible heat damage and rich ones with safe, conservative engine management.

The story of Charles Lindbergh teaching fighter pilots in the Pacific theater to increase their range by leaning the mixture and reducing rpm illustrates that belief. You would suppose that when cruising long distances over open water one would naturally lean the mixture out of concern for one’s own skin. But pilots were apparently not doing it; I suppose because they believed richer was better.

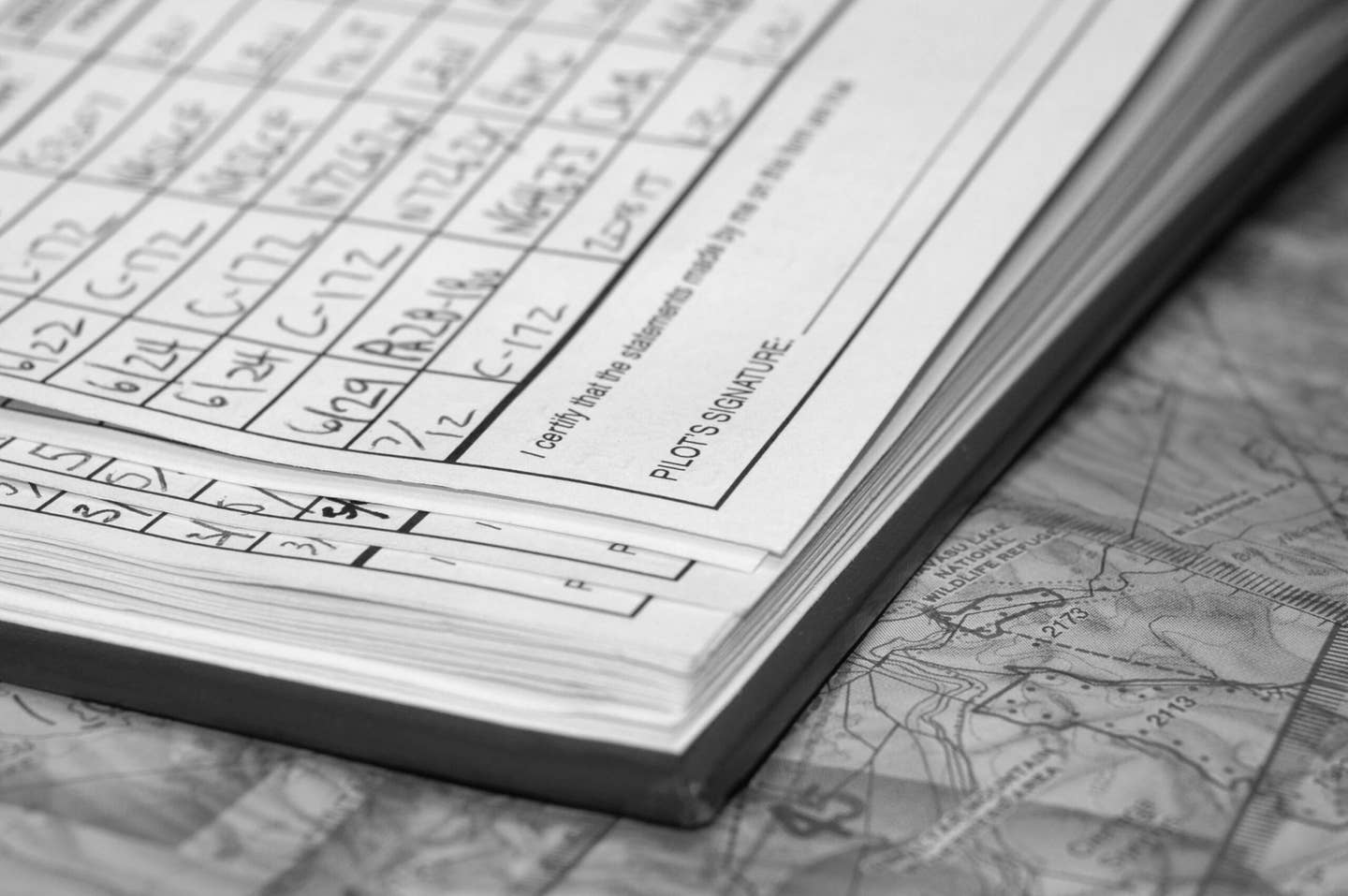

That belief filtered down through flight instructors to their students. When fuel was cheap, flight schools didn’t mind using it for cooling. Proper leaning also requires EGT instrumentation that trainers seldom had, and an attention to engine management that students — not to mention most pilots — did not care to pay. With fixed-pitch props, furthermore, the most salient effect of leaning — only up to a point on the rich side of peak — was to increase power and speed, and that was what pilots liked.

Moreover, many engines, including most carburetor-equipped ones found in trainers, do not lend themselves to LOP operation because of unequal distribution of fuel to the cylinders. If one cylinder becomes so lean that it begins to miss while another is still running at maximum temperature, LOP cruise is impossible.

The engine manufacturers have vacillated on mixture, with Lycoming usually taking the more conservative stance. GAMI — the Ada, Oklahoma, manufacturer of custom injectors designed to even out the mixture distribution among cylinders — strongly advocates LOP operation and, as far as I know, has not had to pay for a lot of melted engines. My own practice is to lean to about 50 degrees LOP immediately after takeoff and stay there, climbing and cruising at 65 percent power or less. As you may guess, I am not uninfluenced by the price of avgas.

Thomas would, no doubt, call me “the idiot that overleans.” He wouldn’t be the first. But at least my cylinders are cool.

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox