To see more of Barry Ross’ aviation art, go to

barryrossart.com.

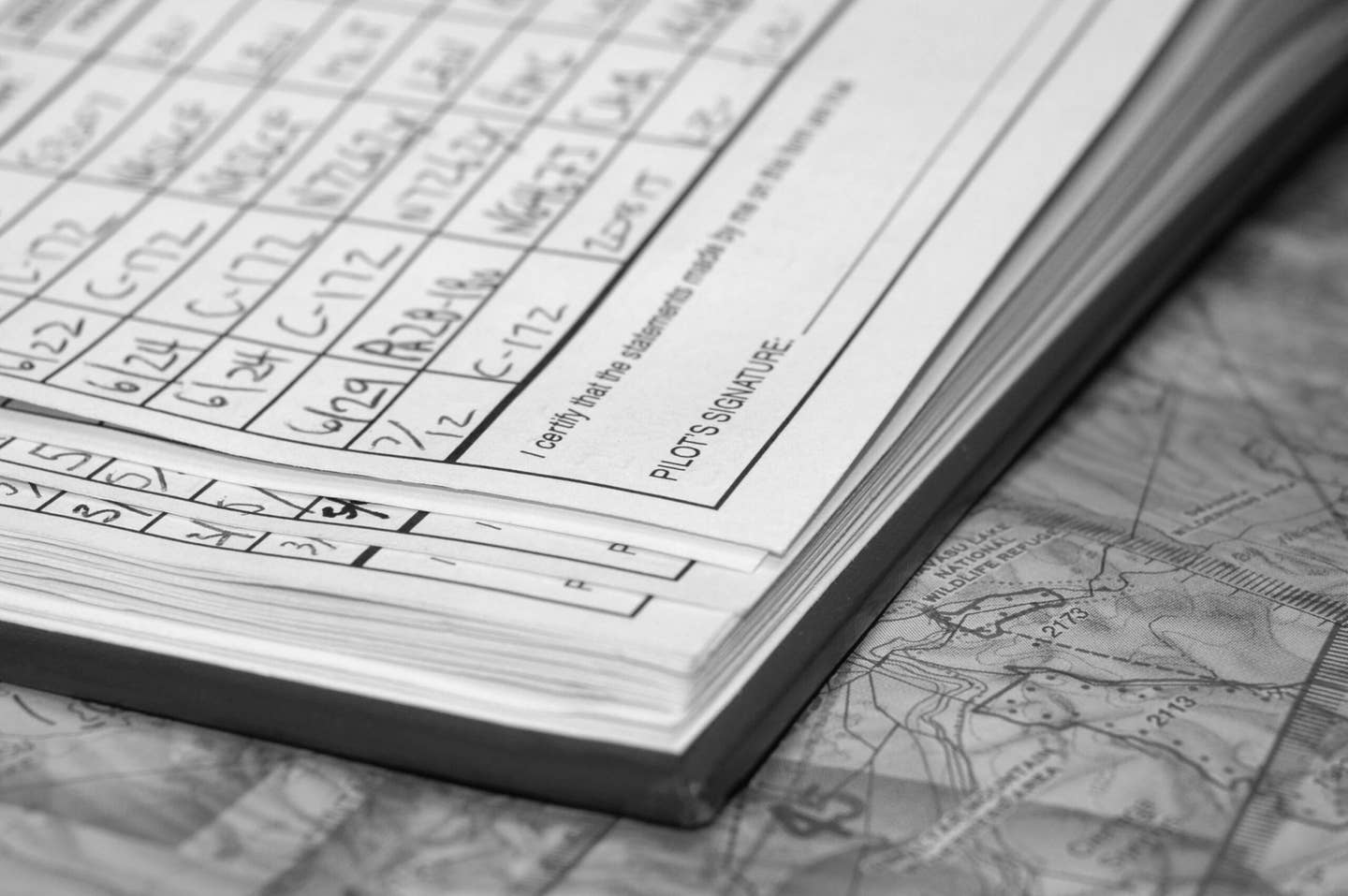

It was a clear but chilly January morning when I arrived at Madison County Executive (MDQ) in Huntsville, Alabama, to return home after my first "real" cross-country flight. Three days earlier I had made the 462 nm journey from my home airport in Liberty, Missouri, to Huntsville. At this point I had roughly 95 hours in my 1977 Cherokee 140 and was thrilled to put my new ticket to use for something that was both practical and fun. The flight in was utterly uneventful, and I had every expectation that the return trip would be the same.

After loading my luggage I preflighted the airplane. Everything looked good — the FBO had filled the tanks, the tires and struts were properly inflated, the oil level was good, and the controls were free and clear. The air temperature was just a bit above freezing, so I let the engine idle for a few minutes after start-up, waiting for the oil temp needle to come off the floor. Once the oil was happy I taxied out, did my run-up and was off.

Winds were calm, and after rotation the Cherokee climbed beautifully through the crisp air. At 500 feet agl I called Flight Service to activate my VFR flight plan and continued to climb. At 1,000 feet I tried to turn out to the west and found my ailerons locked up tight. It took a couple of seconds to sink in — I had no roll control. Not good. Somewhere in my head, images of broken pulleys and jammed pushrods competed with more useful thoughts.

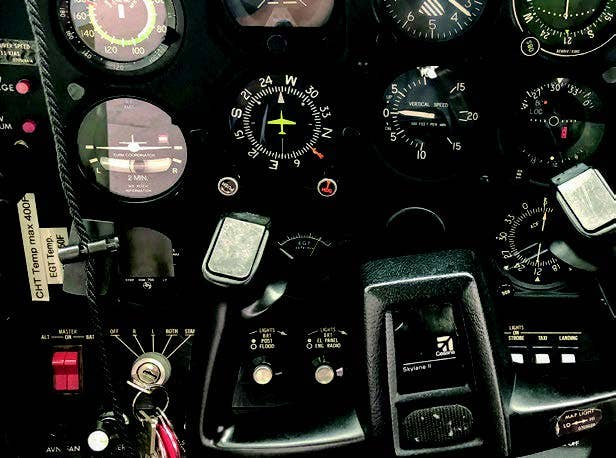

OK, what could cause the ailerons to lock up tight? Well, a few months earlier I had embarrassed myself a bit when I found the ailerons locked while executing the pre-taxi checklist. I wandered into the maintenance hangar and described the situation and one of the mechanics immediately said, "Your autopilot is on. Switch it off. And add that to your checklist." Oops. He was right. I had been playing with the nearly useless wing leveler and had forgotten to turn it off. A simple snap of the switch and all was well.

But this time I knew the autopilot was off. I had added it to my checklist and I had put my finger on it during pre-start. I checked again. It was off. Thinking that perhaps something really strange was happening behind the panel, I snapped it on and commanded a turn. Nada. I turned it back off and still no control. At this point I was probably 2,000 feet agl and still climbing, so I leveled off. Thankfully the elevator was still working fine.

A bit of experimentation showed that I did actually have a touch of aileron control. The left was completely locked, but the right aileron could be deflected a tiny bit. That, plus a heaping helping of rudder, allowed me to turn very slowly. While I made my ugly, skidding turn back toward the field, I called the FBO and asked for suggestions. The manager found a mechanic who suggested it was the autopilot. Nope, already tried that road. Anything fouling the yoke on the copilot side? Nope. Well … "Can you make it back to the field?" I sure hope so.

During primary training my instructor had me practice flying without various controls. Turns without ailerons were in there somewhere. Use the rudder but be gentle. Don't overcontrol. Give the airplane time. Use a slip if the ailerons are locked in an uncommanded turn. Fortunately, mine were locked level so no slip was needed. I just had to take it slowly and make my way back.

After about 10 minutes I brought the airplane back down. Without ailerons I had little lateral control, but the winds were straight down the runway and the approach was stable. The landing was a bit more of a bump than I prefer but nothing that would have drawn attention or ribbing from the more experienced pilots back home. The brakes worked just fine, and I made the second intersection to the parallel taxiway. As I turned, I noticed that the ailerons had magically unlocked. What?

I taxied up to the ramp and was guided over to the maintenance hangar by the mechanic I had been talking with on the radio. I explained what had happened. He had me run the controls through their paces while he watched the surfaces move. Nothing seemed out of place — no friction, no squealing pulleys, nothing stuck in the gaps. He explained that, unless there was something obvious, perhaps behind the panel, he would have to open up all the inspection ports and give the control system the equivalent of an annual. Ouch.

Before he got that far he took a very close look at the ailerons themselves. Sometime in the nearly 40 years since my Cherokee left the factory, some owner had installed gap seals on both the flaps and the ailerons. The mechanic ran his hand between the aileron and the gap seal on the left wing and it came away wet and cold. He turned to me and said, "Ice. I think your aileron froze to the gap seal."

It had rained several times between my arrival and my departure, leaving water sitting on and around the gap seals. On the ground the temperature was above freezing and the controls moved without any problems. One thousand feet above the ground with air shrieking through the narrow gap (aka venturi) at 75 knots, the temperature must have plummeted, turning the thin coating of water into a very effective metal-to-metal ice bond. He described it as "a perfect storm" event — just the right mix of temperature, moisture, airspeed and alignment between the seal and the bottom surface of the aileron.

We dried the surfaces out and then shot them down with silicone lubricant to drive out any remaining water. Before I left, the mechanic suggested I either remove the seals or coat them with some kind of grease. "That extra knot or two probably isn't worth dying for." Words to live by.

At only 100 hours in, this was undoubtedly the most intimidating thing I had faced. It brought home the fact that all the mantras from primary instruction are true: Don't panic; fly the airplane; think it through. It also made me think about ice in a different way. Before, ice wasn't a problem for me because I never flew in icing conditions. Now I know that ice comes in all kinds of flavors, and none of them are your friend.

Postscript: Shortly after this occurred, I posted a quick warning on a forum frequented by Cherokee owners and pilots. Within a day the manufacturer of the gap seals contacted me and asked for a full rundown on the situation. I sent him a detailed write-up and a number of pictures showing the ailerons and the seals. As it turned out, the ice-resistant tape (apparently made from the same kind of plastic as freezer ice trays) had worn away across much of the gap, allowing a metal-on-metal contact. He immediately sent me replacement tape.

Get online content like this delivered straight to your inbox by signing up for our free enewsletter.

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox