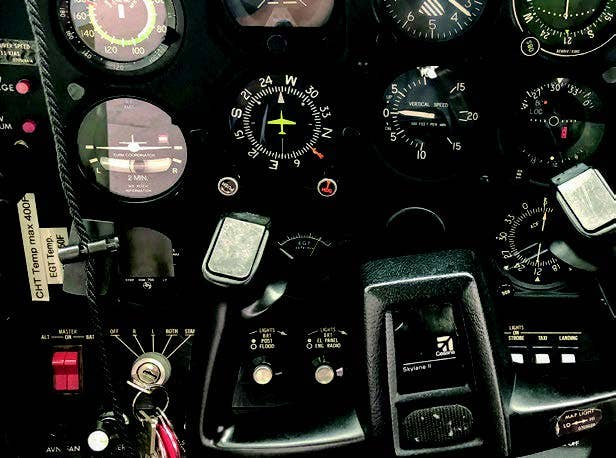

Streamlining means ensuring that the paths of air particles from nose to tail are as smooth and direct as possible. Illustration by Aerologic/Personal Simulation Works

In 1752, an interesting Frenchman named Jean le Rond d’Alembert published a work on fluid mechanics in which he demonstrated that a body moving in a frictionless, incompressible fluid does not experience drag.

This was a consummation devoutly to be wished — we still wish for it today — but since it was quite obvious to anyone whose umbrella had been carried off by a gust of wind that drag really did exist, d’Alembert came to be popularly classified with those legendary scientists, beloved of ignoramuses, who supposedly assert that bumblebees cannot possibly fly because their wings are too small.

Actually, the words frictionless and incompressible were critical to d'Alembert's paradox. He would never have claimed otherwise. Computer programs today that ignore fluid friction, also known as viscosity, are on d'Alembert's side — they reliably report drag coefficients of zero.

Meanwhile, back in the real world, designers sweat bullets fighting their way toward that unattainable zero.

Drag is the thing that makes your airplane stop going faster. A clean single-engine airplane of 300 hp cruising at 175 knots experiences a total resistance from the air of around 350 pounds. It cruises at that speed, and not some other speed, because that is the speed at which thrust — slowly declining as speed increases — and drag — rapidly increasing with speed — become identical. When thrust exceeds drag, the airplane speeds up; when drag exceeds thrust, it slows down.

Drag may be broken down into three types. First, there is the drag created by the mere act of a wing producing lift. This is called “induced drag,” and its existence is related to the fact that the wing has tips around which air spills, imparting a spinning motion behind the wingtips. Of our cruising airplane’s 350 pounds of drag, induced drag contributes only 35 to 40 pounds. Induced drag increases as you slow down; at climb speed, it would be closer to 100 pounds.

A second kind of drag is due to skin friction. The mechanism is complicated; it’s not just a matter of a solid mass of air rubbing like an eraser against the skin. Within a transitional zone, called the “boundary layer,” the speed of air particles relative to the airplane becomes greater as distance from the skin increases. The air in immediate contact with the skin sticks to it, and extremely minute objects on the surface feel no wind at all. Skin friction consists of collisions among air particles moving at different speeds within the boundary layer.

The behavior of air within the boundary layer is exceedingly complex. One simple thing about it, however, is that at the leading edge of a body or wing, the boundary layer is very thin, and the air in it is orderly, moving along in a series of thin films like sheets of paper sliding over one another. This is laminar — which means layered — flow. At some point downstream, these files of marching soldiers (to shift the metaphor) break rank and disintegrate into a disorderly mob. This is turbulent flow. As the boundary layer moves aft, it grows thicker. By the time it reaches the trailing edge of a single-engine airplane wing, it is an inch or two thick; at the aft end of a fuselage, it’s 4 or 5 inches.

The transition from laminar to turbulent flow is easily triggered by small surface irregularities — even smooth butt joints and splattered bugs. The impeccable composite surface of a high-performance sailplane wing may sustain laminar flow more than halfway back to the trailing edge; flow on fuselages and engine nacelles, on the other hand, is almost entirely turbulent. The difference matters because a turbulent boundary layer produces several times more skin-friction drag than a laminar one.

When laminar-flow airfoils were first developed around 1940 by Eastman Jacobs of NACA, they generated great enthusiasm and were eagerly adopted for the new P-51 Mustang. Some bloom went off the rose when it was found that practical-construction metal wings were not smooth enough to sustain much laminar flow. Only recently, with the increasing use of composites in all airplane classes, has it become reasonable to expect laminar drag values from manufactured wings.

Of our airplane’s 350 pounds of drag, 200 to 250 are contributed by skin friction.

A third class of drag is called “form drag.” Form drag occurs when the boundary layer lifts off the airplane surface, allowing eddies of air — analogous to eddies of still water along the banks of a river — to slide beneath it from behind and be carried along with the airplane. The magnitude of form drag is difficult to predict because it is hard to know what pressure is acting on the skin in separated zones. But since skin friction and induced drag are relatively easy to calculate, form drag becomes the difference between them and the actual observed drag.

Today we consider streamlining to be practically synonymous with aeronautical design, but it was only around 1930 that airplane designers began to take it seriously. Streamlining means reducing form drag. It takes two forms. One is the selection of an airplane’s basic shape, including the placement and shaping of windshields, nacelles, wings, empennage components and intersections, and the distribution of the cross-sectional area from front to rear, all intended to provide air with as smooth and direct a path as possible from nose to tail. The other is detail design — the fairing of fixed landing gears, inlets and outlets for engine- and cabin-cooling air, and lots of small items, such as antennas, door handles, flap hinges, tank drains and so on, to minimize the downstream disturbances they produce.

Before and during World War II, NACA tested many full-scale airplanes in its 30-by-60-foot wind tunnel, first shaving off all excrescences, attaching streamlined noses to sealed engine nacelles, filling irregularities and sealing gaps to establish a minimum or baseline drag. The airplane was then returned little by little to its service condition. It was through these tests that the collective impact of seemingly negligible items, like sanded paint on boarding steps, came to be recognized. A fine wire antenna running from the wingtips to the top of the fin of a Republic fighter prototype, for instance, increased its drag by almost 5 percent. It was not uncommon for the sum of insignificant blemishes to peel 30 knots from the top speed of a fighter.

We will never realize d’Alembert’s chimera of a dragless body — but now, at least, we know the reasons why.

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox