First flight of my first homebuilt, Melmoth, at Mojave, on September 6, 1973. Courtesy Peter Garrison

My friend Longbridge has been working for years—these things always take far longer than you think they will—on a Lancair 320 with a lot of airframe mods, the most conspicuous of which are a double-slotted Fowler flap, enlarged empennage surfaces, and leading-edge cuffs on the outer panels of the wings. And then there are the powerplant things—some engine and cooling mods, electronic ignition and so on.

He finally got it finished a few months ago. Then he hired another pilot to do the first flights.

I was surprised. First of all, Longbridge is an experienced pilot himself. He has modified and tested a series of airplanes, all of which he got to go faster and stall slower. So it’s not as if he were a stranger to flight testing. But, to my mind at least, there was the jus primae noctis aspect of the thing. Don’t you want to be the first?

He said three things had entered into his decision. He had no stick time to speak of in Lancairs, the airplane was heavily modified, and he had not flown in the past 15 months.

This got me thinking about first flights.

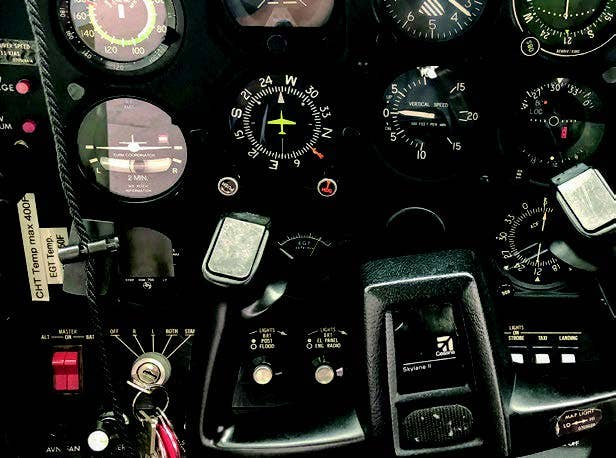

I did the first flights in both of my homebuilts, which were original designs and therefore of unknown quality. I never even gave a thought to having someone else do them. I suppose the same rashness that made me think I could create an airplane made me imagine I was equal to whatever surprises it might spring on me. (A seven-minute video of the first flight of my second airplane can be found on my YouTube channel—my first upload. It’s rather boring but gets livelier at the end. This wasn’t strictly a first flight, though; I had made three long hops on what is now the Mojave Air and Space Port’s 10,000-foot runway the day before.)

I know that a disproportionate number of accidents involving amateur-built airplanes occur on first flights or within the first few hours of testing, and that not everyone is going to be as lucky as I was. In an excellent article on this subject in Kitplanes magazine, Ron Wanttaja reported that during a 10-year period in which more than 10,000 new homebuilts took to the air, about one in 130 first flights ended in a reportable accident or incident. He noted that while this rate is similar to the annual rate for all homebuilts, it represents a single hour of flying rather than a whole year. (He might have added that the annual rate would be lower if the first-flight mishaps were omitted from the denominator.)

The causes of first-flight mishaps break down very roughly into three main categories: builder error, powerplant problems and, finally, our old nemesis pilot error. A catchall fourth category, “other,” accounts for about a tenth of mishaps.

Builder errors can be quite serious and particularly difficult to cope with in flight. Elevators or ailerons rigged backward are almost always fatal—trim not so often, but still a hazard. Missing fasteners, incorrect fastener types (hardware store bolts instead of aircraft ones, for instance), faulty adhesive bonding, loose nuts, missing cotter keys or safety wire—any of these can be hard to spot and can result in a structural failure or loss of control.

The risk of assembly error increases when, as is usually the case, an airplane has been built at home, disassembled, trailered to the airport and reassembled there. I flew my first airplane for 50 hours before I noticed that a bolt connecting a pushrod to a bell crank in the aileron linkage had no nut on it at all. Luckily, gravity had kept it in place.

Read More from Peter Garrison: Technicalities

Most such problems can be prevented by careful preflight inspection using multiple sets of eyes. Just as authors are bad proofreaders of their own galleys, builders are bad inspectors of their own airplanes; other experienced builders or A&Ps should be involved—the more nitpicking and spiteful, the better.

Powerplant issues often involve fuel- system faults and cooling problems. An engine that rapidly overheats forces the pilot to return to land, in a heightened state of anxiety, before having gotten much of a feeling for the airplane. Fuel-feed problems can usually be detected by high-power runs on the ground; the tail should be tied down in order to hold the airplane in a climbing attitude. Some, however, are caused by construction debris in fuel tanks, and these may not turn up until a second or third flight. Fine sanding dust and fibers adhering to the walls of a tank may elude a visual inspection. There have been many instances of loose connections in fuel systems, perhaps because fuel-system plumbing is often assembled and dismantled several times during the course of construction.

Pilot error takes the usual forms: getting too slow in the pattern, overcontrol, loss of directional control during takeoff or landing, ground loops, and so on. A low-altitude stall is the mistake most likely to cause grave harm.

Whether a first flight should be a runway hop or an up-and-away flight is controversial. Neither method is guaranteed. As innocuous as a runway hop seems, it can go wrong. Engines and propellers surge, elevators turn out to be more sensitive than expected (or pilots less sensitive), and the airplane gets too high to get back down within what’s left of the runway. On the other hand, a well-controlled runway hop, just a couple of feet above the ground, gives the pilot a chance to detect nose or tail heaviness, misrig or mistrim, engine feel, and braking effectiveness. The benefits outweigh the risks, in my opinion, but I would take the trouble to find a reasonably long runway, even if it meant some inconvenience.

It’s a mistake to invite friends and family to witness a first flight. The pressure to hurry, to satisfy expectations, to proceed even when feeling misgivings is multiplied by each set of eager eyes. Even factories perform a secret first flight before the public one. It’s better to have a few knowledgeable people in attendance—not as cheerleaders, but as careful observers and critics.

It used to be that only the pilot was allowed to be aboard during the testing phase of a homebuilt airplane’s life. A few years ago, the FAA—reasoning that some mishaps might be prevented if a second pilot, presumably more competent than the builder, were present—has changed that rule. If a more competent pilot is available, you might ask, why not just have the more competent pilot do the first flight? Because it’s a learning experience for the owner.

And this brings us back to my friend Longbridge and his Lancair 320. He had owned and modified an MFI-9 and an RV-7A earlier, so he knows about light stick forces. (He also had a Cardinal, which he cleaned up considerably, but it probably didn’t teach him much that applies to a Lancair.) His engine had already flown 130 hours, so there were no break-in requirements. His aerodynamic modifications were aimed to make the airplane more docile, not less. So why not just go ahead and fly it?

An excess of caution, I guess. Maybe when you’ve been married a couple of times already, the right to be the first doesn’t seem so important any more.

This story appeared in the November 2020, Buyers Guide issue of Flying Magazine

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox