To see more of Barry Ross’ aviation art, go to barryrossart.com Barry Ross

Ferrying light single- and twin-engine airplanes around the world is not a job for the inexperienced or the bold. I am reminded of this fact several times a year on flights in remote parts of the globe.

We all have read stories of pilots who push their luck and lose. Some don’t bother with getting a thorough preflight briefing and find themselves in extreme weather conditions where Mother Nature often wins. The pilot is sometimes taught the ultimate lesson. Many times, just a lack of attention to planning is the cause of an off-airport landing due to fuel starvation. Other times, a thorough walk-around or run-up might have prevented something simple from causing a tragic outcome.

Unfortunately, even the most diligent pilot cannot uncover all the hidden dangers that lurk, or prevent the random failure of a part while in flight. Extra diligence in all aspects of flying can help find the small things that are not “right” before they become something big and cause an inescapable problem. Knowledge, whether learned from personal experience or from someone else’s experience during those all-important flight lessons or “hangar flying,” can help improve one’s chance of survival.

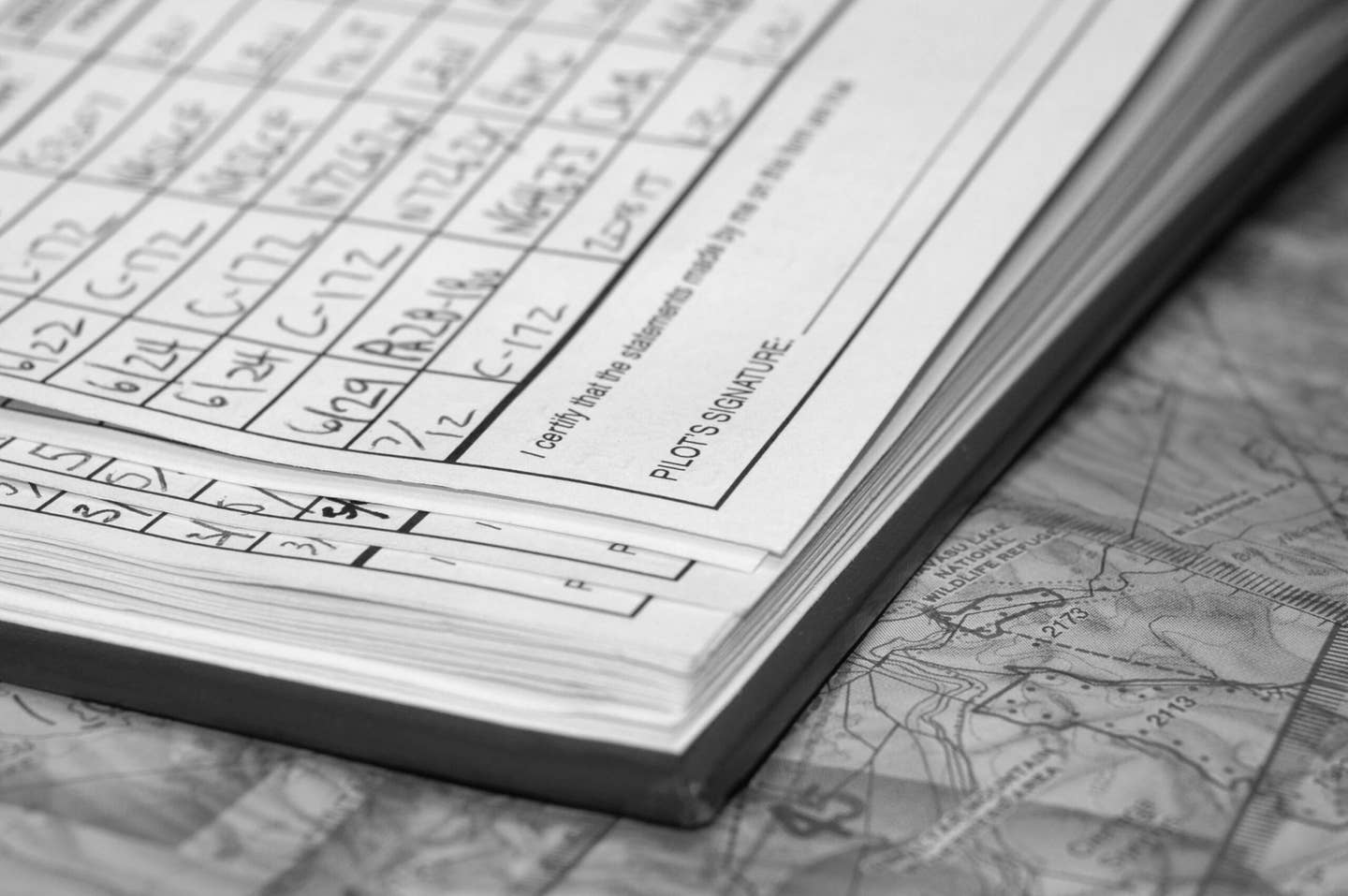

I have been ferrying airplanes around the world since June 2008, and one of my recent ferry contracts was a Cessna 350 from Belgium to Texas. The five-year-old airplane was always hangared and, upon my arrival, appeared in pristine condition. I like to gather as much information as possible about any airplane I am about to take across an ocean, so I read through the maintenance records and logbooks to make sure there wasn’t anything that needed to be corrected. I did a thorough walk-around, familiarizing myself with every inch of the airplane. It was about to become my home for at least 30 hours over the next several days — in this case, weeks. I was putting my life in her hands to safely cross endless miles of often rough and unforgiving seas. How many times as a student pilot or an inexperienced low-time pilot had I blindly hopped into a rental airplane and blasted off for that quick practice flight or to a nearby airport for that hundred-dollar hamburger without even thinking twice about the condition of the airplane? Pilots who rent airplanes put a lot of faith in that FBO to ensure everything is in tip-top condition and all the paperwork is in order.

One important item I have recently started to require before taking an airplane over the Atlantic or Pacific is a compression check of all the cylinders. I have had a few incidents over my nearly 35 years of flying, several being in the last few years while ferrying aircraft, in which a cylinder was weak and caused delays in my delivery. Granted, you can’t check everything before every flight, but the more you check and the more familiar you are with your craft, the safer the journey can be.

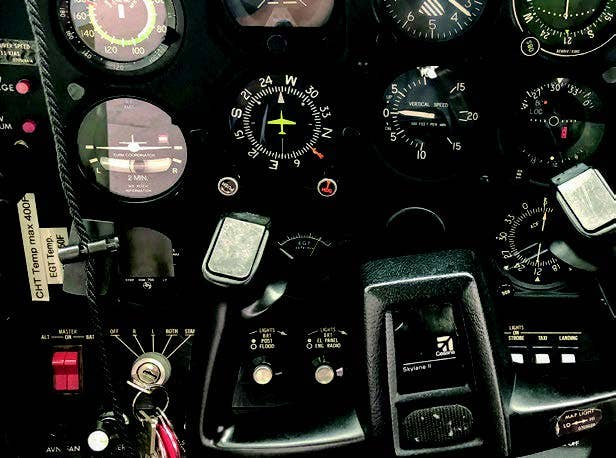

I remember my early hours of flying, hopping into an airplane and taking off to visit friends or flying to the Bahamas to get away from it all, and hardly ever looking at the engine instruments other than to check for an increase in oil pressure after cranking the engine and glancing at the oil temperature before taking the runway for takeoff. Now, however, I am careful to keep an eye on the gauges and monitor them during the flight. For flights that last over an hour or so, I will usually break out my electronic flight bag and start an engine log, for which I have several templates to record the engine parameters depending on the type of configuration. This task is definitely completed on every leg of a ferry, and it was especially helpful on this particular flight after departing from Reykjavik, Iceland, on a cold November morning.

After consulting all the weather data available and phoning for an update of the forecasts, I decided this was the morning to cross the North Atlantic from Reykjavik to Greenland. The plan was to end up in Iqaluit, Canada, that night after a fuel stop in Sondrestrom, Greenland. There was some heavy frost on the exposed surfaces that morning. I removed as much as I could by hand, and then called for the deice truck. The airplane was deiced and given a good coating of anti-ice fluid, and I taxied out to the runway.

Everything was proceeding normally, and nothing gave me any indication of anything amiss on that cold fall morning. After departure, I was given a climb toward Greenland to 10,000 feet. With Keflavik now behind me to the southeast, I leveled off at my assigned altitude and broke out the cruise checklist. After setting the power, I began to lean the fuel mixture to the same flow rate I had on the previous two legs from Belgium to Iceland. Just before leaning to the expected fuel flow, about 2 gph early, the engine gave a loud backfire. Not a good sound to hear when over rough seas beyond power-off glide distance of land. I enriched the fuel flow and started to carefully look at all the engine gauges. Nothing seemed to be wrong with the EGT and CHT readings, but two gauges were acting differently than on the previous flights. The oil-pressure and fuel-flow gauges were fluctuating abnormally. Had I not been keeping careful records on the first two flights, I might not have noticed anything wrong and would possibly have continued on to Greenland. Without hesitation, I initiated a turn back toward land and advised Reykjavik of the problem.

On short final, the Reykjavik tower controller didn’t want me to be surprised as I approached touchdown and advised that he had “the equipment” standing by next to the runway. I wasn’t too concerned, but it was reassuring to know the rescue personnel were nearby. After an uneventful landing, I taxied back to the parking area and shut down. I called my client, and its A&P asked me to do a magneto check to start trying to diagnose the problem. It didn’t take long after taxiing out to the run-up area to discover a rough-running engine while on the left magneto. Due to the remoteness of Iceland, and thinking if one magneto had gone bad with more than 100 hours of operation, the second could be ready to fail too, they decided to ship two magnetos. The magnetos took a total of four days to arrive and clear customs.

Since it was too late for anyone to work on it the afternoon the magnetos arrived, I repositioned the airplane to the maintenance hangar the next morning. The A&P was fairly busy with his own airplanes but finally started work that afternoon. He found the problem was not a bad magneto but a plug wire that had become almost entirely disconnected. In fact, all the plug wires on the bottom of one side of the engine had not been securely torqued after the compression test. He tightened down all the wires, and the cowling was put back on so I could do another run-up to check the engine. It was perfect. I thanked the mechanic, paid my bill and parked the airplane back by the FBO. Now it was time to start looking at the weather again for another opportunity to depart for my next stop — and check and recheck absolutely everything.

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox