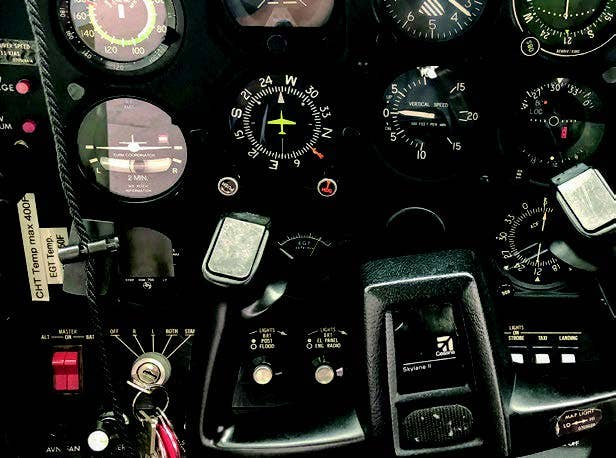

Whether you operate on the rich or lean side of peak EGT, make sure you understand proper leaning technique. And know this: If you want to fly fast, you must operate rich of peak; lean of peak is for economy only. Jon Whittle

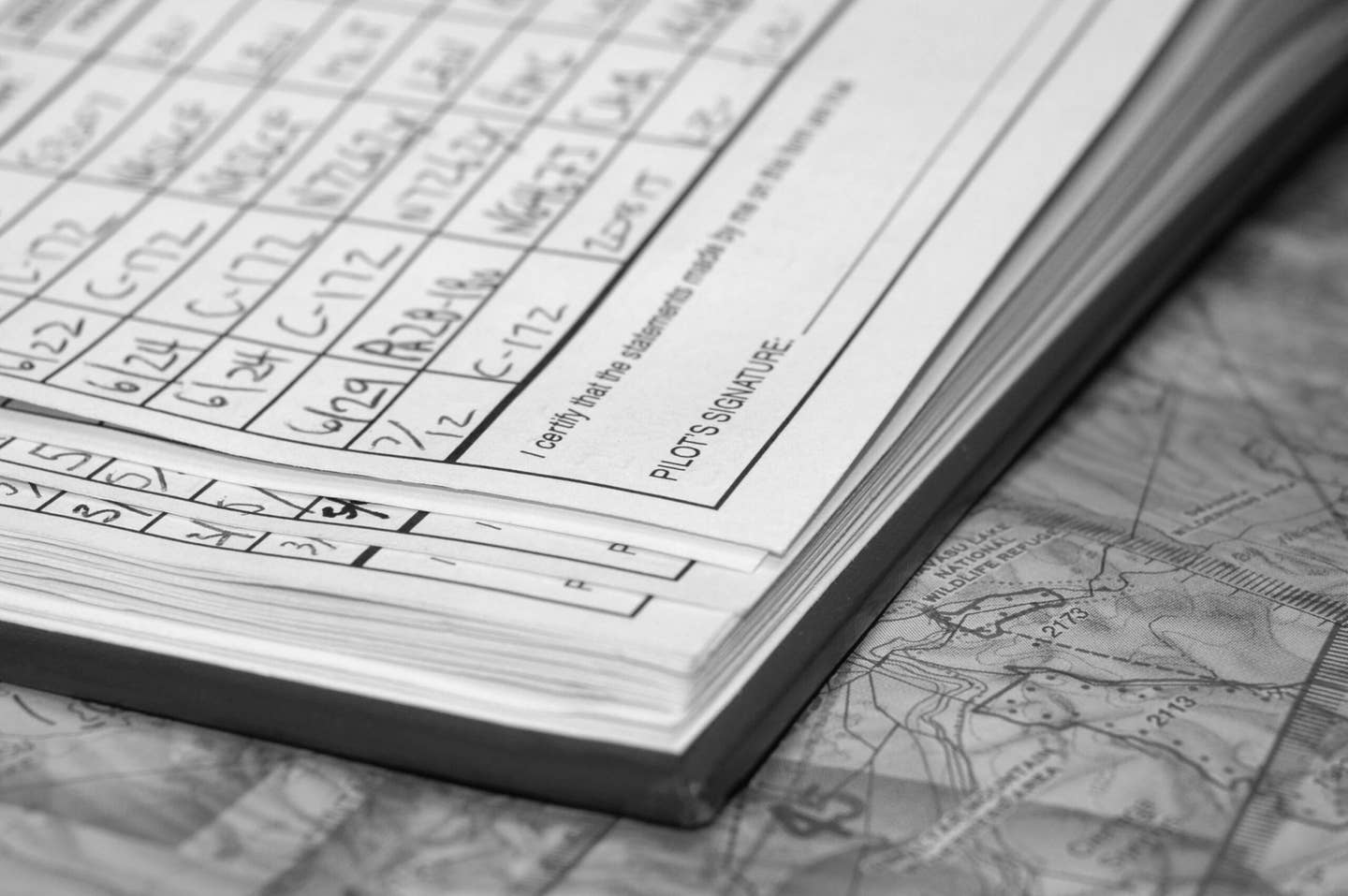

If you want to ensure your engine has the best chances of reaching TBO and beyond, here’s advice that could end up saving you big time: Stop listening to all the supposed “experts” in airport coffee shops and online forums who claim they know it all. There’s a good chance they don’t — and the wisdom they spout could be the polar opposite of how you should be caring for one of your biggest aviation-related investments and the one piece of equipment you literally can’t afford to have fail at the wrong time.

One of the easiest ways to ensure your engine has a long and healthy life is to follow the manufacturer’s recommendations, not what the guy in the hangar next door says works for him. Proper maintenance is the key. And one of the biggest overlooked maintenance items is routine calibration of the engine-driven fuel system. The instructions for continued engine airworthiness from Continental Motors, for example, state that the fuel system should be calibrated at every annual inspection or 100 hours, whichever comes first. Some mechanics skip it. Others claim they do it, but they might be doing it improperly because they lack the proper tools.

You can probably guess why regular calibration of the fuel system is important. If the engine isn’t receiving the correct amount of fuel for the power demanded, you run the risk of detonation in flight, as well as valve and cylinder problems in the future if the fuel-air charge entering the cylinders is wrong. As you fly along with an out-of-tolerance fuel system, you might not even realize you have a problem. Quite often the damage occurs slowly over time as an accumulation of strain to internal components.

Another common problem many aircraft owners face is engine damage resulting from corrosion in airplanes that have sat for extended periods. In many cases, when an engine doesn’t reach TBO it can be traced to the fact that the aircraft hasn’t been flown much since its last overhaul. In fact, Continental and Lycoming add 200 hours to the recommended TBO for many of their engines if they consistently run more than 40 hours per month. The old adage is true: Engines need to be run or expensive things inside start to break.

The cooler you can keep your cylinder-head temperatures, the better off you’ll be in general, but you shouldn’t be running your engine at reduced power settings all the time under the faulty assumption that you’re preserving the internal components and increasing your chances of reaching TBO. By all means, if your goal is to save fuel, operating at lower power settings is fine, but piston aircraft engines also need to be flown hard on occasion — especially a brand-new engine or one just out of overhaul.

“There’s a tendency to want to baby the engine,” says Neal George, an engine-tech guru at Continental Motors, “because it’s an expensive item on the airframe. But the worst thing you can do is baby a new engine out of the box. They need to run hard. They’re intended to run hard. We designed our engines to operate from zero time to TBO in the 75 percent power range.”

Common Misconceptions

Some aircraft owners are perfectly happy to fly for an hour on the weekend at reduced power settings, say 55 percent, at low altitude doing the same little tours, and then come back, do a landing and put the airplane away. If that fits your typical flight profile, you might want to rethink your strategy. You’re never really operating at high enough power settings to prevent problems. If you repeat this kind of flying month after month, you could end up with significant deposits, which can rob your engine of power and lead to engine damage.

On every flight, you want to elevate the oil temperature high enough that all the humidity inside evaporates. But that alone isn’t good enough. Say you fly your airplane with its Lycoming IO-360 for an hour at a reduced power setting of 55 percent. You’ll reach the recommended 180-degree oil temperature needed to burn off moisture, but what you’ll fail to do is exercise your engine’s half-wedge compression rings, which requires higher power settings to prevent excessive oil from remaining on the piston walls, potentially causing glazing. Once you have glazed cylinders, you can expect oil consumption to rise, and possibly a big bill for cylinder-bore honing and a new set of rings.

One of the worst things you can do to your engine is come out to the airport and start it without flying just to circulate the oil. What you’ve done instead is create a breeding ground for corrosion. If you know you won’t fly your airplane for a month or more, your strategy should be to run it hard, get the engine good and hot, and then do an oil change immediately when you land. Your cylinders will thank you. If you won’t be flying for an extended period — generally defined as more than 90 days — you’ll want to have your mechanic follow the procedures for long-term storage.

Another topic that’s rife with confusion and misinformation is the discussion about operating rich of peak (ROP) EGT versus lean of peak (LOP). Before you adopt one mixture-leaning strategy over another, you obviously need to do your homework. Either practice is fine, as long as you know what you’re doing — and your airplane is approved for LOP operation, which allows you to save fuel and run at cooler CHTs but isn’t recommended for every engine. Be careful you don’t heed the advice of pilots in coffee shops in lieu of cracking open the engine and airplane operation manuals and taking the time to understand the procedures that were created by the engine maker and incorporated by the aircraft manufacturer.

Rich vs. Lean of Peak

If you’re not well versed in the science of ROP vs. LOP operation, here’s a brief primer: In an engine that is running with a “perfect” fuel-air mixture, all the fuel will completely burn during the combustion cycle. This results in the highest exhaust gas temperature, also known as peak EGT. For maximum power, the fuel-air ratio should be about 10 percent ROP. For maximum economy, about 10 percent LOP is the target. One potential problem is that to reach LOP you must transition through peak EGT — but not long enough to cause harm. A bigger concern is that because not all the cylinders operate at the same fuel-air ratio, you might have one cylinder set for LOP operation but be running another cylinder too hot. This makes it crucial to have an engine analyzer with probes that read temperatures for all cylinders, not just a single cylinder.

Here’s the major point many people are missing in the whole ROP vs. LOP debate: If you want to fly fast, you need to be operating ROP; if you want maximum fuel economy, you can fly LOP. Keep in mind, though, that you’re not going to get economy and speed flying LOP. Where people get into trouble is when they start to play around with LOP operation, visit the online forums, listen to the LOP “experts,” and gradually start to modify what they learned in the beginning. They end up setting the mixture for LOP operation but then decide they’re going too slow, so they add a little power without readjusting the mixture. Suddenly, they might be barbecuing a perfectly good cylinder.

Bottom line: If you want to go fast, stick with ROP. If you want fuel economy, aren’t concerned with going as fast as you could, want cooler CHTs and EGTs, have the proper engine analyzer and a fuel-injected engine, and are willing to take the time to learn the proper procedure, by all means, give LOP a try. I fly LOP in my turbocharged Cirrus, which has GAMI-calibrated fuel-injection nozzles and a lean-assist blue target line that matches fuel flow with the proper LOP setting. I’ve also taken the time to learn how to adjust for LOP without the handy blue line. When I fly airplanes with carbureted engines or only a single-cylinder CHT or EGT probe, I fly ROP, period.

Engine analyzers are excellent not just for monitoring temperatures but also for spotting spark plug and magneto problems early. Often, you can even download the data to see a snapshot of what was going on inside your engine at a given time. For long-term trends, oil analysis can help you catch engine trouble early. Oil analysis is like sending a sample of your blood to the lab — it can reveal a surprising amount of information about the inner workings of your engine without invasive surgery. Keep in mind that you’ll want to send multiple samples to the same lab at set intervals since one analysis can’t provide the trend information you need.

It’s also a good idea to have your mechanic check the accuracy of your gauges. You might be operating your prop at precisely 2,400 rpm, but if it turns out the prop is actually turning at 2,550 rpm because of a faulty gauge, your assumptions about how you’ve been operating your engine are incorrect — and you could be exceeding manufacturer-recommended parameters. The older the airplane, the more likely the gauges are off.

You’ll also want to be sure your mechanic checks the magnetos. The typical inspection interval for mags is every 100 hours. Magneto inspections often get missed, and they can snowball into other problems such as hard engine cranking and the need to replace the starter.

Of course, frequent oil changes are an important maintenance consideration if you hope to reach TBO (which is a manufacturer recommendation, by the way, not an airworthiness limitation). The jury is still out on oil additives. Some mechanics recommend a pint of CamGuard after each oil change to aid with corrosion protection. Your friendly AeroShell rep would probably tell you that stuff isn’t needed. Be sure to check with the engine manufacturer before putting any additives in your engine because you might void your warranty, even if an additive is FAA-approved.

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox