The distinction between skin and frame is not always easy to make. Media Storehouse/FlightGlobal

In our March issue, a short article about the Vulcanair V1.0 — an Italian four-seater strongly resembling a Cessna 172 — mentioned that it uses "a steel-frame and aluminum structure, which was the standard for decades."

I beg to differ.

It’s true that the Vulcanair has a steel frame under its aluminum skin — I suspect only in the vicinity of the cabin — but it is not quite true that this has ever been the standard style of construction, let alone for decades. It is a relatively unusual hybrid of two styles. Two other companies that have used this system, Mooney and Meyers, come to mind; I’m sure there have been others.

Owners of airplanes built this way often claim that the steel cage in which they sit makes them safer, but the manufacturer’s reason for using it might have been something else entirely. Thin-walled steel tubing, welded into a web of triangles, does make a rigid and light structure. It is also convenient. Hard points for attaching wings and landing gear are easily provided. Big holes for windows and doors can be readily framed. Perhaps more important, a hacksaw, a file, a welding rig and a fixture to hold things in place are all the equipment a fledgling amateur builder or an undercapitalized startup needs to get into airplane building. For all these reasons, steel-tube frames, usually skinned with wood and fabric, were prevalent well into the 1930s. They remained popular with homebuilders until, in the 1960s and ’70s, first aluminum and then composite structures supplanted them.

A steel cage sounds safe, but where crashworthiness is concerned, the lightweight truss-work surrounding the cabin of an airplane is a far cry from, say, the roll cage of a race car. It is approximately similar in strength to an all-aluminum or all-composite structure, as it logically must be since airplanes are designed not to be superfluously strong but rather as weak as they can be while still fulfilling federal certification requirements. Strength is weight, and weight is bad. As we have learned from well-publicized efforts to make cars safer, the crashworthiness of a passenger compartment owes more to astutely designed energy-absorbing “crumple zones” extending outward from the cabin than it does to a superstrong shell or cage immediately encasing it.

The type of structure that has actually been “the standard for decades” among airplane manufacturers is aluminum semi-monocoque. This was the structural medium of every Cessna, Beech, Piper, Boeing and what-have-you built in the half-century following World War II.

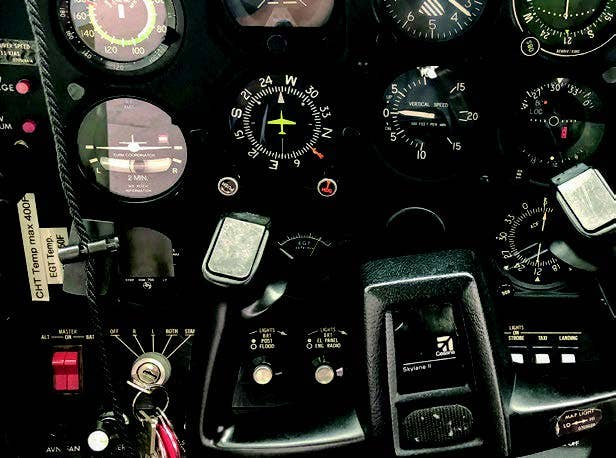

The term monocoque, which means “single shell,” properly denotes structures that have no internal framing whatsoever. A tip tank, for instance, might be a pure monocoque: Its outer shell carries all the weight of the fuel, without any internal spine or frame other than whatever local reinforcement is required for attachment to the wing. A fuselage could be a pure monocoque, but large cutouts for doors and windows, and hard points for attaching wings and engines, require local reinforcements that begin to look something like a partial frame. Consider, for instance, the fuselage of a Cessna Skyhawk. Open the doors, and there appears to be almost nothing between the tail cone and the engine. All the loads pass through the floor, the ceiling and the windshield posts. Strong built-up sections surround and reinforce the door and window openings. From the point of view of crashworthiness, there is no reason these bent and stamped aluminum angles, channels and box beams should be inferior to a welded-steel frame.

The distinction between skin and frame is not always easy to make. If you peer back into the tail cone of any metal airplane, you see a series of sheet-metal rings, typically a couple of feet apart, that give the cone its shape. A number of stiffeners, extruded or else bent up out of sheet metal, run lengthwise. Although this internal structure gives the impression of being a “frame” — and indeed the ringlike elements happen to be called “frames” — it is actually a collection of stiffeners that are loosely connected to one another, if at all. It has no integrity of its own. Take away the outer skin, and the internal elements sag shapelessly or fall to the ground.

Stiffeners are needed because, in sheer volume, the largest structural member in an airplane is its skin. For the airplane to be light, the skin must be thin, but the thinner it is, the less able it is to carry loads, especially compressive ones, without deforming. Typically, the aluminum skins of airplanes in the under-4,000-pound weight class are between a 30th and a 50th of an inch thick. Thinner skins imply a more efficient structure, but one that requires more closely spaced stiffening members and is accordingly more costly and labor-intensive to manufacture.

Thin skins betray themselves by a wrinkly or wavy appearance under load, and by more numerous lines of rivets where internal stiffeners are attached. Thicker skins, though heavier, require less internal stiffening and so can be smoother. If you compare a Cherokee’s wing to a Bonanza’s you readily see the difference; the skins of the Piper are smoother and the rows of rivets are farther apart. The difference is due in part to Piper’s desire for simplicity and low parts count, but also to the hope that by eliminating rivet lines ahead of the main spar the Cherokee (or the earlier Comanche) might get a little speed benefit from its laminar-profile wing.

Surface smoothness is a much-touted benefit of composite construction. Presumably, it contributes something to performance. There is ample experimental evidence of the drag penalty associated with surface roughness or waviness. Any self-respecting sailplane uses extreme laminar profiles, well buffed, and its pilot will notice changes in its behavior when raindrops disturb the flow on its wings. But most of the surface area of a sailplane is wing. How large the benefit of smoothness is on airplanes with comparatively high wing loadings — airplanes, that is, whose wings account for a relatively smaller fraction of their total drag — is more doubtful. The difference between a dirty surface and a clean one is a fraction of a fraction. Nevertheless, it is indisputable that if you carefully wash and polish the bug cemetery that is your leading edge you will notice that your airplane flies a little faster, just as, after you clean the windshield of your car, its engine runs more smoothly.

Although aluminum monocoque construction is still the standard today, it is gradually giving way to glass- and carbon-fiber composites, which have, in addition to the virtue of surface smoothness, those of superior strength-to-weight ratio and of ready formability to any desired shape. A more subtle, but not negligible, asset of composites is the unitary quality of their construction. Unlike aluminum structures, which are stitched together out of many small panels using thousands of rivets, composite structures tend to be made in single large parts — half of a fuselage, or the top or bottom of a wing. These major components are then bonded on long, lightly loaded seams, eliminating the stress concentrations that can lead to eventual fatigue and cracking in a riveted sheet-metal structure.

This physical continuity of structure is a property that composites share with frames of welded steel tubing. Their joints too consist of continuous and homogeneous material, without a distinct boundary between a part and its neighbor. Those who built airplanes of welded steel in days of yore must have been in disbelief when newcomers — who turned out to be prophets of the future — proposed discarding an internal frame entirely. How would they build the airplane? Out of a patchwork of metal sheets. And how would they connect them together? Why, by punching holes along the edges, sticking nails in them and squashing them flat!

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox