A bump in the night. Barry Ross

In 1986, I flew a Beechcraft Baron 58 each night carrying canceled bank checks from Baltimore to Richmond, Virginia; Charlotte, North Carolina; Philadelphia and back to BWI, departing at about 10 p.m. and returning by 6 a.m. the next morning. I was part of a network of check-carrying general aviation aircraft that crisscrossed the nation each night.

On one particular mid-September night, the flight from BWI to RIC was uneventful. I taxied in and unloaded the checks into a waiting truck and headed to the FBO to await the bags of checks for the leg to Charlotte.

Once loaded up, I got my IFR clearance and taxied to Runway 20. A few minutes later the Baron lifted into the cool September air with a right turn that headed me toward the South Boston VOR at 6,000 feet. The route took me southwest past Greensboro, North Carolina, and then into Charlotte. I flicked on the autopilot and tuned the number two comm radio to 123.45 to see what the other freight dogs were chattering about. Hearing no one, I pulled out the World War II paperback I had been reading called Fly for Your Life. Operationally, the engines sounded normal except for a propeller that occasionally demanded I use a quick knuckle twist to put the props back in sync.

At about 1:30 a.m. ATC told me to expect a visual approach to 18 Left at Charlotte. The approach controller descended me from 6,000 feet to 3,000 feet and then to 2,300 feet for the visual. I of course used the normal check-runner profile, power-on high-speed descent, keeping the speed at redline, until I heard a strange sound: One of the props out of sync again—but which one? I moved the right prop control back, but nothing changed.

I tossed the book over my shoulder and turned out the overhead light to give the Baron my full attention. I pulled the propeller control back a little more, but still no change. I’d never experienced anything like this. Then I noticed the right tachometer needle was past redline.

I reduced power to slow down when the entire plane started to shake—not vibrate, but violently shake. I reduced the throttle to idle and pulled the prop lever back more to no effect.

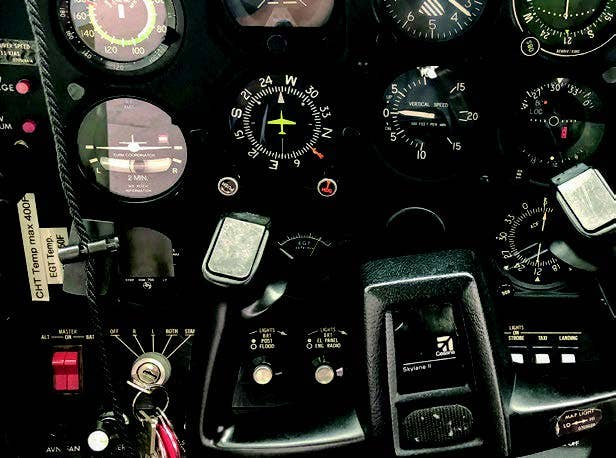

My airspeed was so high that I raised the nose gently to slow down while simultaneously going through my mental engine-shutdown checklist. Then I performed it, slow and direct. As I moved the right propeller lever to feather, it stopped about halfway and would not feather. By now, the airplane was shaking so badly I couldn’t even read the flight instruments.

Then, strangely, time slowed down, with everything moving in perpetual slow motion. I saw my life flash in front of me. I was a baby, a toddler, grade schooler, college student. I saw my parents, a coffin. At 2,500 feet I wasn’t sure I could make it to the airport. I called ATC.

“Uh...Congressional 100. We have a problem, sir.”

I started slamming the prop control up and down, but it stopped half way. I did it harder, finally all the way back to feather. Wham! The plane shuddered, then got smooth and quiet as the shaking stopped. That’s when I realized the right propeller had ripped through the nose of the Baron.

“Ah, Congressional 100. We just lost a prop!”

I could see only half of one blade of the right propeller. The spinner was gone. I also saw metal sticking up around the nose of the airplane through the windshield. The sound of the left engine was now calming, and I knew I could make it to the airport, even though half the propeller and counterweights on the right had gone through the Baron’s nose.

I remember telling Charlotte Approach that I was the only person aboard along with about 50 gallons of fuel. The controller asked if I had Runway 23 in sight. I got a little confused and forgot which runway I was headed for since I always landed on 18L at CLT. I’d never landed on 23 and couldn’t pick it out from the city lights. I could see 18L, but not 23.

“You want us on 18 Left?” I asked.

“I have you set up for Runway 23 straight in,” the controller responded. I told him I didn’t see it yet. “OK, turn 5 degrees left. Five miles from the runway. Are you able to maintain your altitude?”

“Yes, sir,” I said. “We’re doing all right, but could you turn the runway lights up all the way, sir?”

“Sure will. And I’ll vector you to the runway, Congressional 100.”

Once I saw the runway, the controller said, “Cleared visual approach Runway 23. There’s an Aerostar landing Runway 36 Right that will hold short of your runway.”

“Congressional 100, contact the tower now on 118.1. The equipment is standing by for you. Good night.”

When I was certain I had the runway made, I lowered the first 15 degrees of flaps and then the landing gear. That’s when I heard a strange kerklunk sound from the front of the airplane.

“Can you tell Congressional 100 if you see a light in the nose?” I asked the tower controller. “I’m not sure if the nose wheel is going to make it down because it’s torn up.”

This Baron had a taxi light on the nose gear. I had checked it during prefight, and it had worked during the taxi out at Richmond. The controller said he’d look for the light. He saw a light but couldn’t be sure if it was on the nose gear, so I wasn’t sure the nosewheel was down.

I continued the approach and touched down on the main wheels holding the nose up as long as I could. I brought the left engine to idle and the mixture to cut off. The nose wheel touched down the way it was supposed to and the airplane quietly rolled to a stop. The runway edge lights were the only lights I saw.

I sat for a moment in the dark, and then found my flashlight and opened the door. I stood on the right wing shining my light on the half propeller and all the jagged metal in the nose. Suddenly I heard a terrifying noise and shined my light toward the back end of the Baron.

Out of the darkness rushing toward me were alien spacemen—actually, they were airport firefighters in their silver suits. They took off their hoods to reveal earthly humans, asking, “Are you OK?” “Yeah, I’m fine,” I said. Suddenly my mind snapped back to business. “My checks!” Without asking, I opened the Baron’s back door and started heaving my check bags onto the nearest fire truck. “Take these checks over to my courier, and can you hurry?” They took the bags and we made the cut off time.

A little later I learned the right propeller was due for an overhaul. The propeller’s broken counterweight band that stuck in the nose had an oxidized section followed by a clean break. During the overspeed, the band had broken loose and lodged itself between the propeller and the spinner, which is why I couldn’t feather the prop. The violent shaking had broken the motor mount in two places, leaving the engine hanging down. Just an inch aft of where the propeller blade had entered the fuselage was a fully charged oxygen bottle. I guess it just wasn’t my night to go.

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox