The Fizzled-Out Promise of the Lockheed ‘Flatbed’

The concept aircraft would utilize an open platform and various modules to carry a wide variety of loads ranging from military equipment to passengers.

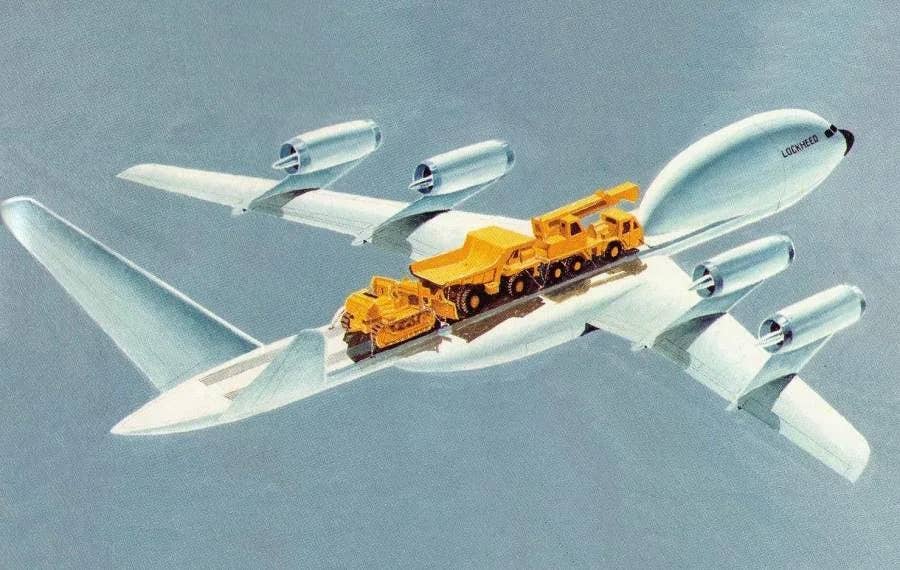

Unconventional in many respects, an initial study found the Lockheed ‘Flatbed’ concept both technically and economically feasible. [Credit: Lockheed]

In 1980, a small team of engineers from Lockheed explored a bizarre concept, the likes of which had never been studied before.

The group recognized that the transport aircraft category traditionally comprised three separate subcategories—passenger, cargo, and outsized cargo. It then created a concept that would combine all three. Aptly called the “Flatbed,” the concept aircraft would utilize an open platform and various modules to carry a wide variety of loads ranging from military equipment to passengers.

The most unconventional aspect of the Flatbed was the proposal that large pieces of military equipment be carried out in the open, completely unsheltered from the wind and elements. The team selected two sample military vehicles for the initial study, an XM-1 tank and an M60 bridge launcher, weighing 115,000 and 120,000 pounds, respectively. The big question was could this sort of outsized cargo effectively be carried out in the open at hundreds of miles per hour?

The group got to work on the drawing board and in the wind tunnel to answer that and explore how the Flatbed might serve as a multifunctional, “do-it-all” transport solution. The baseline Flatbed aircraft was a low-wing, turbofan-powered aircraft approximately the same size and weight as an Airbus A300. It utilized four CFM-56 engines, as found on the Airbus A320, Boeing 737, and Boeing KC-135R Stratotanker, and was optimized for a 2,600 nm range.

Recognizing that carrying outsize cargo such as tanks out in the open would present serious drag and fuel-burn penalties, the team did not hedge its bets on this configuration alone. Instead, it designed the Flatbed to accept a variety of pressurized and unpressurized containers as well as a passenger module. The entire nose section of the aircraft was hinged, capable of being swung to the side to enable modules and vehicles to be quickly and easily loaded and unloaded using a variety of ramps, rollers, and latches. Raised engine pylons extending above the wing rather than below enabled shorter landing gear and a low, 7-foot cargo bed height.

With the cargo and passenger modules, the Flatbed was shown to be “generally fuel efficient in comparison with reference airplanes,” burning approximately 11 percent more fuel than a conventional design and targeting a 0.82 Mach cruise speed in these configurations. The primary benefit was presented as efficiency with regard to loading and unloading, particularly in the passenger configuration. In this role, the team proposed an entire restructuring of point-to-point travel.

By utilizing a large number of removable 180-seat modules, the passengers could board their module in a city center some distance away from their departure airport. Like multimodal containers, the module could be loaded onto a short-distance commuter train for transport to the airport, where it would be expeditiously loaded onto the waiting aircraft. The team proposed that this speedy loading and unloading of passengers would enable quick turns and high aircraft utilization. Similarly, it touted the ability of multimodal containers and even train cars to be quickly rolled onto and off the Flatbed.

But from the perspective of aircraft design in general and aerodynamics in particular, the most intriguing aspect of the Flatbed concept was the carrying of outsize cargo out in the open. Using scale models of both the Flatbed and tank and bridge launcher, aerodynamicists studied drag figures and later translated the data into speed and fuel-burn figures. The resulting performance numbers indicated the concept was surprisingly plausible.

Naturally, carrying external cargo was found to drastically increase drag compared to carrying the aerodynamically slick cargo and passenger modules. At higher altitudes, carrying the tank or bridge launcher would result in a 20 percent increase in fuel burn. At a lower 18,000 feet cruising altitude, this increased to approximately 55 percent. The external cargo also lowered the cruise speed to 0.5-0.6 Mach.

The team proposed multiple solutions to address the increased fuel burn. At the time of the study, engine manufacturers were looking at unducted “propfan” engines to improve fuel efficiency, and the team suggested exploring these new engines for the Flatbed. It also explored the possibility of “vortex control,” a system that introduced suction at the forward end of the cargo bed to smooth the air flowing around the back of the cockpit section, thus reducing drag.

Ice accumulation on external cargo was identified as one potential challenge worthy of additional study. Engineers did observe that in-flight icing “does not appear to present a major problem,” however, as ice formation occurs only on the front part of the aircraft components. By tucking in the external cargo behind the cockpit section, it appeared to be sufficiently shielded from ice.

While the Flatbed concept would never materialize beyond static and wind-tunnel models, the team partnered with NASA to publish a detailed initial study that evaluated the feasibility of the unconventional concept. The study ultimately concluded that the concept was both technically and economically feasible. They reasoned that the smaller size and increased versatility of such an aircraft would make it inherently more efficient to operate compared to existing military cargo aircraft.

Despite the overall finding that the Flatbed concept was worthy of additional examination, however, no such study ever occurred. The Lockheed Flatbed concept fizzled out after the publication of the NASA report.

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox