A great maintenance technician is truly a pilot’s best friend. IndustryViews/Shutterstock

It wasn’t a hung start, exactly, but it wasn’t a normal start either. The N2 spun up smartly and fuel flow was normal. The engine began to accelerate, but then it hesitated. The interstage turbine temperature, which had been rising normally, had a sinking spell. Before I could think to do anything about shutting off the fuel, the engine began to accelerate again and started normally. The facts at hand were not encouraging. The starter generators had just been recently overhauled. These Williams FJ44-1A jet engines are expensive. (When I bought the airplane, the broker said, “You are buying two engines and a maintenance program; they throw in the seats and pressurization essentially for free.”) No question, guidance was required. “Better call Hector” was my first and only instinct.

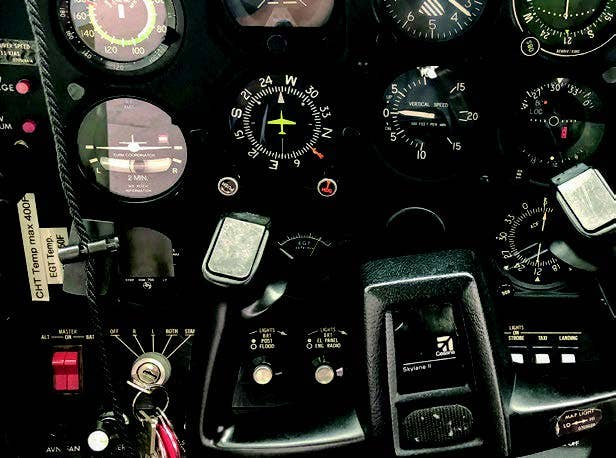

You don’t own an airplane for very long before you become acutely aware of an intimate relationship among the airplane, its owner and competent maintenance. This lesson was obvious early in my ownership journey. I had just gone with a shop on the field (Midway International Airport in Chicago) to do an annual on our new-to-me Cessna 210. During the inspection, the nose-gear doors were “adjusted.” On a post-maintenance test flight, the nose-gear doors got stuck and the nose gear failed to deploy. The sound of the fuselage on runway concrete is never to be forgotten. Silver lining? I met the first “real” mechanic of my airplane-owning life, John Daraska, and the insurance brokers I have used for the past 45 years, Wenk Insurance.

John was based near my hangar at Midway in the late ‘70s and early ‘80s. He was my kind of guy—straightforward, not given to small talk, smart, experienced and possessed of unusual common sense. One day, I loaded up my family and took off for Detroit. On rotation, the power seemed to sag a bit, but engine indications were normal. I thought that I had underestimated our takeoff weight, but it soon became obvious that we needed to land. We staggered around the pattern and made it back to an actual runway. On the ground, the run-up was normal. My 4-year-old son said, “Wow, we’re in Detroit already.” My feet were shaking on the rudder pedals.

John said he’d have a look. When I called him, he said that the run-up was normal, but he’d “take it for a spin.” He called back, “That damn thing almost killed me.” He quickly diagnosed an exhaust obstruction, and I trusted him completely thereafter. There is something about a good mechanic that can make almost any situation better.

When I was grounded one Sunday in Peoria, Illinois, John flew down to replace a starter and get me home in time for work on Monday. He was that kind of man. In the ‘80s, John trusted me on a human-body-maintenance matter. To my lifelong regret, I let him down. I had lunch with him near Midway just a few years ago and told him so.

Read More from Dick Karl: Gear Up

I thought I might be spoiled by John’s competency and had little hope for finding somebody of his caliber when I moved to Tampa, Florida, but a neurosurggeon friend recommended Bill Turley at Aircraft Engineering in Bartow. Thus began a 38-year friendship. Bill talked me through some harrowing moments of aircraft ownership. When I met him, I had a Cessna P210 and—close to my chest—held hopes for a twin. He treated the 210 as if it were his. While some big shops are of the “you need a new engine” school and other mechanics are of the “some speed tape and bailing wire ought to take care of the issue” philosophy, Bill was complete and safe without any propensity to dart down distracting (read: expensive) rabbit holes.

When I had a Cessna 340 picked out to buy, I went to Bill for a pre-buy inspection. He looked up at me from under the cowling of the left engine and said, “I could annual this for you for about $50,000.” I sent the broker back to Kansas in the airplane she came in.

When my flying life peaked with the purchase of a Premier jet, I was on my own. Maintenance was to be provided by Textron Aviation or well-known big Premier shops in Rockford, Illinois, and Sacramento, California. Each worked diligently to solve a persistent “roll-fail, speed-brake-fail” fault that was first noticed on the delivery flight. Providence bailed me out by sending a pelican into the left wing, bending a spar and exposing me to a hard truth: Textron had no real interest in supporting orphaned Beechcraft Premiers.

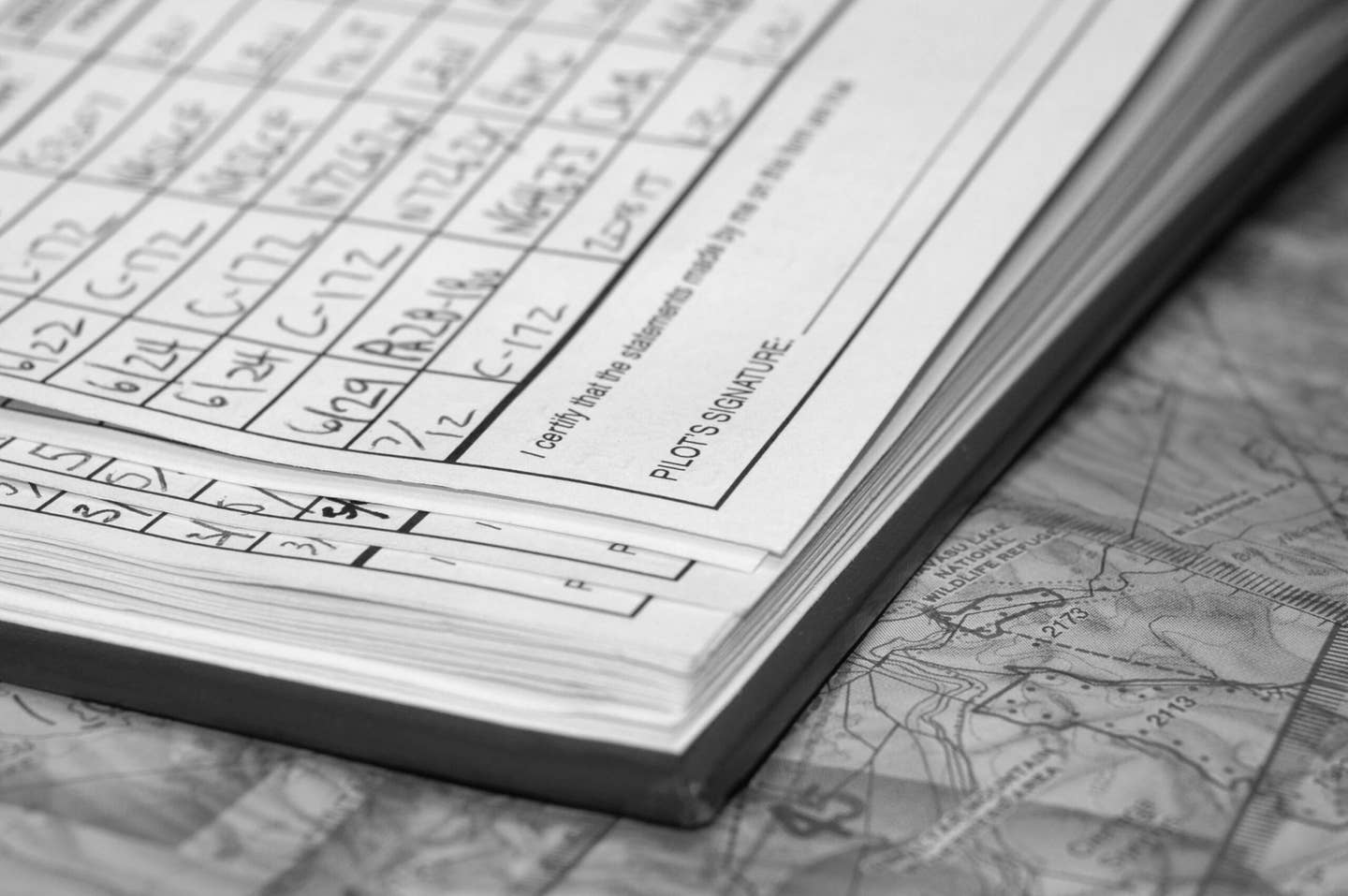

Saved by avian intervention, we bought a Cessna Citation CJ1. This airplane fit us like a glove—and I knew I needed some professional advice to manage the jet. During the pre-buy I hired Eric Meitner, a former Cessna maintenance guru now operating a consulting service. He reviewed the logs and CAMP (computerized aircraft-maintenance programs), Cessna’s choice of maintenance-tracking services. When confronted with a fuel leak on delivery day, I was dumbfounded and confused. I called Eric. He had a few pointed words with the technician who had serviced the airplane, and the issue was fixed—pronto.

As if guided again by providence, I then found a man in a maintenance “cage” in my hangar. His name is Hector. He fixed a nav light, and I wrote him a note of thanks. “I like that,” he said. “That’s old-school.” We’ve been friends ever since. Hector is a full-time employee of a large company and manages big jets. After hours, he helps me. For a modest monthly sum, I have access to decades of experience and hundreds of contacts.

It is obvious that a well-maintained airplane is axiomatic to pilot confidence. What’s subtler is the rich set of friendships and large dose of camaraderie that comes down from a pilot’s dependence on a good mechanic.

This story appeared in the August 2021 issue of Flying Magazine

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox