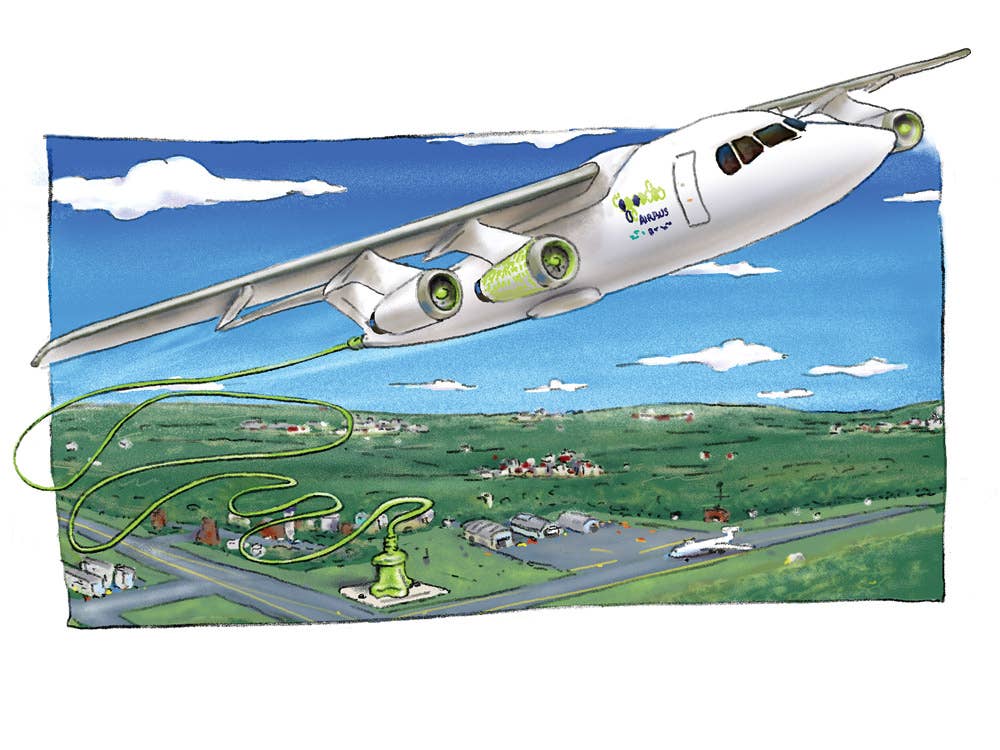

“A further gain in efficiency would come from charging the battery on the ground, because grid energy is cheaper than that in hydrocarbon fuels” Illustration by Philippe Lechen

I have been inclined to class electric airliners, along with personal jet packs, among the consumer products that will always be almost here. My estimates of the likely future, however, have almost an inverse predictive value: If I say something is utterly impracticable, it will very likely be for sale at Walmart next year.

The case for skepticism about electric airliners is strong. The crux of it is energy density. Fossil fuels store many times as much energy per pound as batteries do, and weight is the enemy of flight. The Tesla Model S sedan, the poster child for electric vehicles, achieves a couple of hundred miles’ range with 1,200 pounds of batteries plus a not negligible amount of power modulation equipment between batteries and motors. An airplane could fly the same 200 miles at the same 80 mph or so with 70 pounds of avgas.

Nevertheless, in accordance with the Garrison rule of inverse predictive value, there must be electric airliners ahead.

Current commercially available batteries have around 1/50th of the energy density of hydrocarbon fuels. But that is not the only thing that matters. There is also the efficiency with which a motor uses that energy, and here electric systems far outshine internal combustion engines, converting three or four times as much of the energy in their “fuel” into useful work. If instead of energy coming in we look at power going out, the relative disadvantage of batteries drops from a hopeless-sounding 50:1 to a merely desperate 15:1.

Cheerleaders for an all-electric future extrapolate from the steep improvement in battery energy density over the past few decades to a future in which batteries attain practically any energy density you choose to name. But battery chemistry is not a ballistic object whose future trajectory can be predicted from its past motion. Batteries came a long way from lead-acid to lithium polymer, but that does not prove that they will repeat the leap.

Nevertheless, an Israeli firm called Eviation is purportedly developing a 9-passenger, 14,000-pound all-electric airplane for air-taxi use.

With three 350 hp electric motors, two at the wingtips and one at the tail — all ideally positioned for prop strikes, by the way — and 4,000 pounds of batteries, the V-tail, low wing airplane, called Alice, projects a cruising speed of 260 knots at 10,000 feet and a 650-nm range.

The published numbers don’t make much sense to me. The range seems to require a three-hour flight duration, but I don’t see how a 260-knot speed could be maintained at 10,000 feet by an airplane the size of a PC-12 with much less than 900 hp continuous; yet the battery capacity is said to be only 1,200 hp/hr. The claimed approach speed of 100 knots also seems inconsistent with a wing loading that must be in the neighborhood of 50 pounds per square foot. (One of the drawbacks of batteries is that, unlike fuel supplies, they do not get lighter as power is used.) But perhaps these numbers will be modified after the prototype flies; it wouldn’t be the first time.

Notwithstanding the obvious inadequacies of present batteries and the uncertainty surrounding future ones, electric power systems for airplanes, including airliner-sized ones, have been in development for several decades, with major players such as Boeing, Airbus and NASA taking part. Airbus is now moving forward into larger hardware, with a program that will replace first one, then two of the turbofans on a four-engine BAe146 regional jet with electric fans.

But these will not be powered by batteries alone. The power plants will be hybrid systems in which electricity is supplied by an internal-combustion engine driving a generator. The generator output feeds electric motors, and they in turn spin propellers or fans.

This sounds circuitous; if we’re back to relying on hydrocarbon fuels, what’s the point?

The expected gain is incremental, and arises from the peculiar duty cycle of an aircraft power plant. Airplanes use lots of power to take off and climb to altitude; they require much less in efficient cruise. But internal combustion engines tend to be most efficient at high power; so, in effect you would like to have a big engine for takeoff and climb and swap it for a smaller one for cruise.

A hybrid system does this, in effect, by using a small, efficient fuel-burning “sustainer” engine for the cruise segment and by taking a surge of supplemental power from the batteries for takeoff and climb. Some of the output would be used to partially recharge the batteries, as could wind- milling propellers during the descent — although any power harvested from windmilling propellers would increase the rate of descent. A further gain in efficiency would come from charging the battery on the ground, because grid energy is cheaper than that in hydrocarbon fuels, and could, in principle, come from non-polluting, renewable sources. The analogy to plug-in hybrid cars is obvious.

Series hybrid power systems are not new. Diesel-electric power has been in use in locomotives, ships, submarines and a few buses and trucks for a century. The challenge for aviation is to identify the best way to combine the components and exploit their strengths.

The strengths of electric motors, apart from their efficiency, include compactness, light weight, simplicity and very high reliability. Their compactness encourages “distributed propulsion” schemes in which motors are placed, for example, on wing- tips to increase effective wingspan by “unwinding” tip vortices — hence the Alice’s tip-mounted motors — or many small motors are strung out along the leading edge of a wing to increase its lift at low speeds. More ambitious schemes include pivoting these motors to provide vertical takeoff, but as a matter of simple physics vertical take- off is incompatible with efficient operation over long ranges.

If the Eviation all-electric approach seems to stretch current technology to the breaking point, a Washington state startup called Zunum, with some backing from Boeing and JetBlue, is taking a more conservative, stepwise approach. Its 12-seat ZA-10 design is similar in size (and in its use of a V-tail) to the Alice, but 2,500 pounds lighter. (On paper, of course — every- thing is lighter on paper.) It has a couple of 650 hp ducted fans mounted on the aft fuselage, just as turbofans would be. In addition to an unspecified mass of batteries in its wings, it uses a 650 hp turbine generator as a “range extender.” For short stages, however, battery power alone would suffice.

This arrangement raises interesting issues around redundancy.

Is this a single-engine airplane, or a twin? If a twin, it must always hold enough electric power in reserve to allow for a landing, including a possible go-around, in case of a failure of the sustainer. But that means that it must haul around lots of extra battery weight that it will probably never use.

When I visited Zunum’s website, I was struck by something I hadn’t expected. The “our team” pictures show a bunch of jolly, jeans-clad people, mostly quite young. Not a tie in sight. The feeling is extremely Silicon Valley. I imagine them working in one of those unpartitioned, well-lit spaces with limitless supplies of coffee and chocolate-chip cookies, where new machines are defined not by their parts (3-D printed, naturally) but by their software.

And indeed, Zunum and Eviation mention, rather casually, that their airplanes will be fly-by-wire and pilot optional. So, you see, there is more going on here than just the scaling up of electric model airplanes.

There is a rethinking by people — many of whom, I suspect, did not come up through the legacy aviation companies — of what an airplane is and how it ought to work. “We are dreamers,” they declare; and if their dreams come true, pilotless electrified air taxis will be humming into and out of small suburban airstrips a few hundreds of miles apart, fueled by energy har- vested from wind and sunlight.

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox