An Introduction to Your Aircraft Starter

The accessory facilitates engine starting so that you can do so from the comfort of the cockpit.

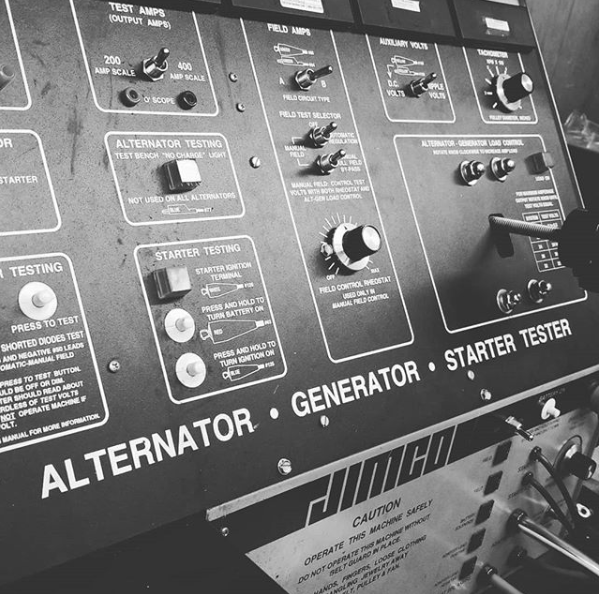

Starter tester. [Credit: AC Accessories of OK]

“Clear prop!” is one of the most commonly heard phrases at any general aviation airport. It is generally followed by an aircraft engine bursting to life, spitting fire, and burping smoke. What makes all that possible? Why, the aircraft starter motor, of course.

And what if it doesn’t? Suppose a turn of the key is met with the "wrrr, wrrr, wrrr" you loathe to hear. It can be pretty embarrassing—all of your friends hanging out on the ramp, staring. You know what I am talking about. GA airports are like little ecosystems; everyone has their place, and they all know your business.

Now, what do you do? Everyone starts talking amongst themselves, and the kids ask a million questions. Sorry, guys. It doesn’t appear we are getting that hundred-dollar hamburger. You know what time it is. When you get back from Krystal, it’s time to start troubleshooting.

History of Hand Propping

In days of old, airplanes sat cold before starters were invented. Some were blue, said "this will not do, should be a better way," they hinted.

Yes, it is true. Before electric starters, pilots had to hand prop their aircraft to get it started. Some of you Cub flyers will recognize this. When my colleague Jason McDowell profiled the Piper J-3

he highlighted “airplanes that lack electrical systems, hand propping is necessary.” Thankfully we have progressed and can now start aircraft from the comfort of the cockpit. That is when it works. All right, gang, let’s get started. See what I did there?

Hand propping is a nice trip down memory lane, and we could also discuss Hucks and pull starters, but there isn’t space or time for that. My goal is to give you relevant, actionable information you can use today in maintaining your aircraft.

In this piece, we focus on electric starters for Lycoming applications. Rest easy, Continental types; we will get to you, I promise. Rotax, your time will come as well. If anyone out there still flies Franklin aircraft engines, give me a call, and I will see what I can do.

Aircraft Starter Maintenance, Troubleshooting

In early aircraft designs, weight was a constant concern. Aircraft mirrored starting methods of the times, and many machines required hand cranking for ignition. At some point between the World Wars, the electric starter came into favor. This was less cumbersome than hand propping, especially on engines higher off the deck—and safer.

Today we’ll focus on the electric direct drive starters for reciprocating Lycoming applications. The big Continentals use a starter adapter, a subject we shall delve into later. This intel is a good jumping-off point to understanding general aviation starters.

Checking in with Lycoming engines in Williamsport, Pennsylvania, they offer the following guideline on How to Clean Your Direct-Drive Engine Starter, specifically the Prestolite or Electro Systems models. Lycoming cites dirt and environmental contamination as one of the leading causes of starter failure. The Bendix drive (the part of the starter that, once energized, engages the starter ring gear) is open to the elements and continually accumulates particulates that hamper operation and cause it to stick.

Lycoming also publishes Service Instruction SI-1528 to address starter overheating. A snippet from this SI reads: Overheating is usually induced by an excessive duration of time used for the starting attempt (commonly referred to as a “crank”) and an excessive number of starting attempts that are not within a designated time period (commonly referred to as a “duty cycle”).

When I was in the service, pulling duty meant work. The duty cycle for an aircraft starter motor is the same thing. Hartzell Engine Technologies produced a short video entitled Understanding Your Aircraft Starter’s Duty Cycle, which can help explain the concept. You may recognize the Hartzell name but associate it with propellers. You would be correct, but know they are also in the engine accessory business now.

Hartzell is making a name for itself in the general aviation space and now has several divisions obtained by acquisition. One such entity is Quality Aircraft Accessories, Inc. (QAA) in Tulsa, Oklahoma. I know this shop well; we did business for years when I had my engine shop. They have an excellent tutorial on aircraft starters that you can peruse and help build your knowledge library.

Sky-Tec is another Hartzell brand. I’ve included their troubleshooting guide for those with these models in the fleet.

B&C Specialty Products, Inc. has a line of PMA/STC aircraft starters offering new products and overhaul services. Their B&C Starter Troubleshooting Guide is full of detailed explanations and is required reading for anyone maintaining their products. Another great resource is their reference library.

Even the best cared-for parts eventually fail. Once you have exhausted all avenues for maintaining your starter, you may realize it is better to be safe than sorry and repair or replace your tired old unit. This brings us to our next spirited debate, overhaul versus replace with new. Which are you? Team OVH or Team NEW?

Before answering that, consider what the experts say about this issue.

Let’s go back to Hartzell and check in with one of their discussions on the repair or replacement of your aircraft starter. It is interesting to note that, according to the company, “Hartzell is no longer manufacturing or overhauling Bendix-type starters.” Such is the price of progression.

Aircraft Spruce & Specialty advertises an older MHB-4016 overhauled starter, but they are currently at zero in stock.

Another shop that did work for me in Tulsa was Aircraft Accessories of Oklahoma, including starter work. I spoke at length with them recently about their recommendations when it came time to service a Lycoming starter. Echoing what Hartzell mentions above, the old Bendix-style heavyweight starters are not economical to return to service any longer. Not only are they labor-intensive, but the spare parts are tough to come by as well. They recommend replacing it with a newer lightweight unit also.

During our discussion, I learned that the shop still maintains a robust business overhauling Bendix and Jack & Heintz starters for radial engines. There you are, Pratt & Whitney R-1340 Wasp and R-985 Wasp Junior maintainers; give AC Access of OK a call if you need starter work.

Checking in with JD Kuti with Pinnacle Aircraft Engines in Silverhill, Alabama, he echoed the sentiment to use new lightweight starters for their Lycoming engine overhaul jobs. He will install overhauled starters for their Continental work. Why is that, you ask? Keep an eye out for our CMI starter article coming soon.

Starter Replacement Identification

Starter identification is straightforward, and the first place to check is the aircraft’s technical publications. In May of this year, we discussed the Illustrated Parts Catalog (IPC) to help identify the correct spare parts approved for your aircraft.

As you can see on the Lycoming 0-360-B20 IPC, the model starter is LW-15572, a 24-volt unit with 12/14 pitch pinion. If that part number looks foreign to you, it’s because almost no one identifies accessories by the Lycoming number. They use the more familiar OEM Prestolite MHB-4016.

You will also note that Lycoming offers an OEM solution for a lightweight option in the form of a kit, part number: 05K21302-2. Both the heavy and lightweight starters deploy a 12/14 pitch. This refers to the gearing and must align with the starter ring. For this application, the starter ring gear is part number: 72566, found on page 10 of the IPC. The ring gear can be procured at Aircraft Spruce and changed in the field, although I recommend having your friendly neighborhood engine shop take care of it.

If you want a quick reference guide for Lycoming starters and alternators, check out Service Instruction No. 1154W, a one-stop shop for identifying what you need.

It is good to see businesses investing in general aviation. We mentioned Hartzell Engine Technologies LLC earlier. They also have a resource for their Starter PMA Eligibility, complete with FAA supplement data.

We mentioned Sky-Tec earlier. Here is their application information.

B&C Specialty Products publishes a catalog of its products also. Make sure you download these and keep them in your digital library, or bookmark them for easy access later.

No aircraft parts shopping trip is complete without a stop at Aircraft Spruce & Specialty. This is a great place to check the starters and make notes.

There you have it, folks, everything you ever wanted to know about aircraft starters and much more. OK, no, but this should get you in the ballpark so you know which questions to ask. At least now, when you pull the bird out of the hangar, yell clear prop, and hear "wrrr, wrrr, wrrr," you won’t feel lost.

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox