Top Aircraft Maintenance Trends for 2024

What to expect in the new year.

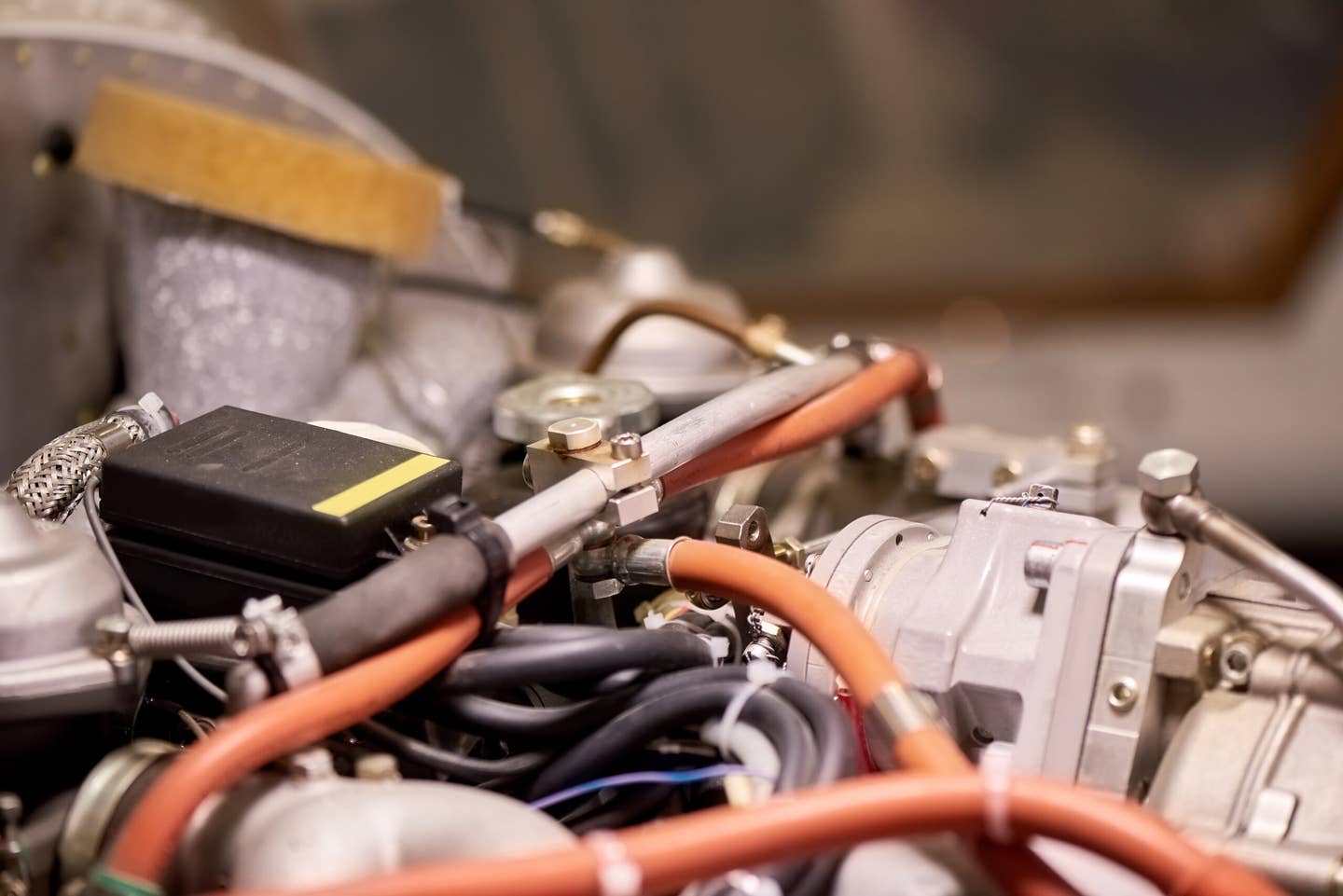

What trends will rise to the top for aviation maintenance operations in the coming year? [Shutterstock]

When the holiday lights fade and faraway relatives return to their lands, it is finally time to pick up the pieces of your life, wipe off the New Year's Eve glitter, and brace for the inevitable. It is time to go back to work.

Ah, yes, there are reports that need writing, oil that needs changing, and wrenches that require spinning. As idle hands are the devil’s workshop, let’s take a page from our British cousins’ playbook and “best get on with it.”

The year gone by, 2023, leaves us with more questions than answers, and in aircraft maintenance, that is not a good thing. We know that interest rates are up, consumer confidence is down, and the prop on the airplane spins around. That is about the extent of it.

Planning out one’s actions need not cause dread. With the proper intel, opportunities exist, even in a down market. The best thing to do is map out a strategy, stick to the plan, and hope for the best.

While I do not claim to hold all the secrets of tomorrow, there is enough industry chatter to give us a rough idea of what will come. After consulting aviation experts, here are my top guesses for aircraft maintenance trends in 2024.

Air Traffic Increase

Topping the list of aircraft maintenance trends is an increase in air traffic. FAA representative Angela Stubblefield recently said: “The No. 1 trend is the rebound and continued increase in air traffic.” What does that have to do with maintenance, you say? More flight hours and cycles equal an accelerated maintenance schedule. Oil changes, tire replacements, and even windshield wiper blade swaps increase the more you fly.

I believe business and GA travel is better than flying commercial. When I travel by air in a Beechcraft, chances are I am friends with the pilot and have a connection to them. With everyone cramming back into the airline terminals at KATL, the same percentage of folks are headed to their GA airport.

This leads us to another factor to consider: ground traffic at airports. This can elicit a greater chance of hangar or ramp rash for aircraft. Have you ever taxied too far to port or starboard to avoid another aircraft? In doing so, if you hit a taxi light, your engine could suffer sudden stoppage. You know what that means. Call your insurance broker.

Spare Part Material Cost

Have you been to the store recently? Aircraft part costs are increasing. The supply chain has yet to recover from COVID 19 pandemic-induced shuttered factories, reduced inventory levels, and personnel layoffs.

Locatory.com, an aircraft parts e-commerce platform, tackled this subject in a recent article. While acknowledging some recent gains in the spare parts arena, it said “evident shortages persist due to a complex interplay of factors.” This leads to cost increases, parts scarcity, and long manufacturing lead times.

It is the simple law of economics. Anytime demand exceeds supply, the price goes up. This is different from discretionary spending too. To fly, one must maintain. It is possible to skip maintenance, although no one recommends that.

Sustainability

As you most likely have guessed by now, sustainability will always make the list of trends. It must. As aircraft evolve, our processes, practices, and policies need to follow.

Solutions provider Poente Technical offers this insight: “With a heightened focus on environmental sustainability, MRO [maintenance, repair, and operations] in 2024 will witness an increased integration of eco-friendly practices. From using sustainable materials in repairs to implementing green technologies in maintenance processes, the industry is aligning with global efforts to reduce its carbon footprint.”

Couple that with the move to unleaded avgas, and we will have plenty to discuss in 2024.

Technical Labor Shortage

Finding technical talent is challenging enough, but the departure of experience during the pandemic makes it even harder now. This predicament is not going to get better anytime soon. What is the industry doing about it?

General Electric discusses apprenticeship programs, building partnerships, and trying new models to recruit and retain workers. It has successfully partnered with the state of Massachusetts to attract and train technical talent.

Programs aside, there must be a way to get the youth excited about aviation again. Events held during National Aviation Day are a good start, but we cannot simply focus on this need one day a year. We need more involvement, much earlier than in college, when students have already chosen a career path.

Predictive Maintenance

Most people associate predictive maintenance with major airlines, but there is a growing trend for business and GA. This will need to develop over time, but we can stay close to the airlines and track their progression. Any advancements in that area will eventually flow down to lighter aircraft.

Why is predictive maintenance so essential? Brighter Directions puts it this way: “Delays in flights due to a potential malfunction, the anxiety of having a safe flight across borders, expensive tickets due to continuous upkeep, etc., are a few of the many factors that can be resolved through predictive maintenance.”

We will investigate these topics and more over the coming months. So everyone gets settled, buckle in, and prepare to taxi into 2024. As always, drop me a note and tell me what I missed.

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox