Archer Installs ‘Automotive Style’ Air Taxi Battery Pack Production Line

The electric vertical takeoff and landing (eVTOL) manufacturer says its newly installed battery pack manufacturing line is capable of producing up to 15,000 per year.

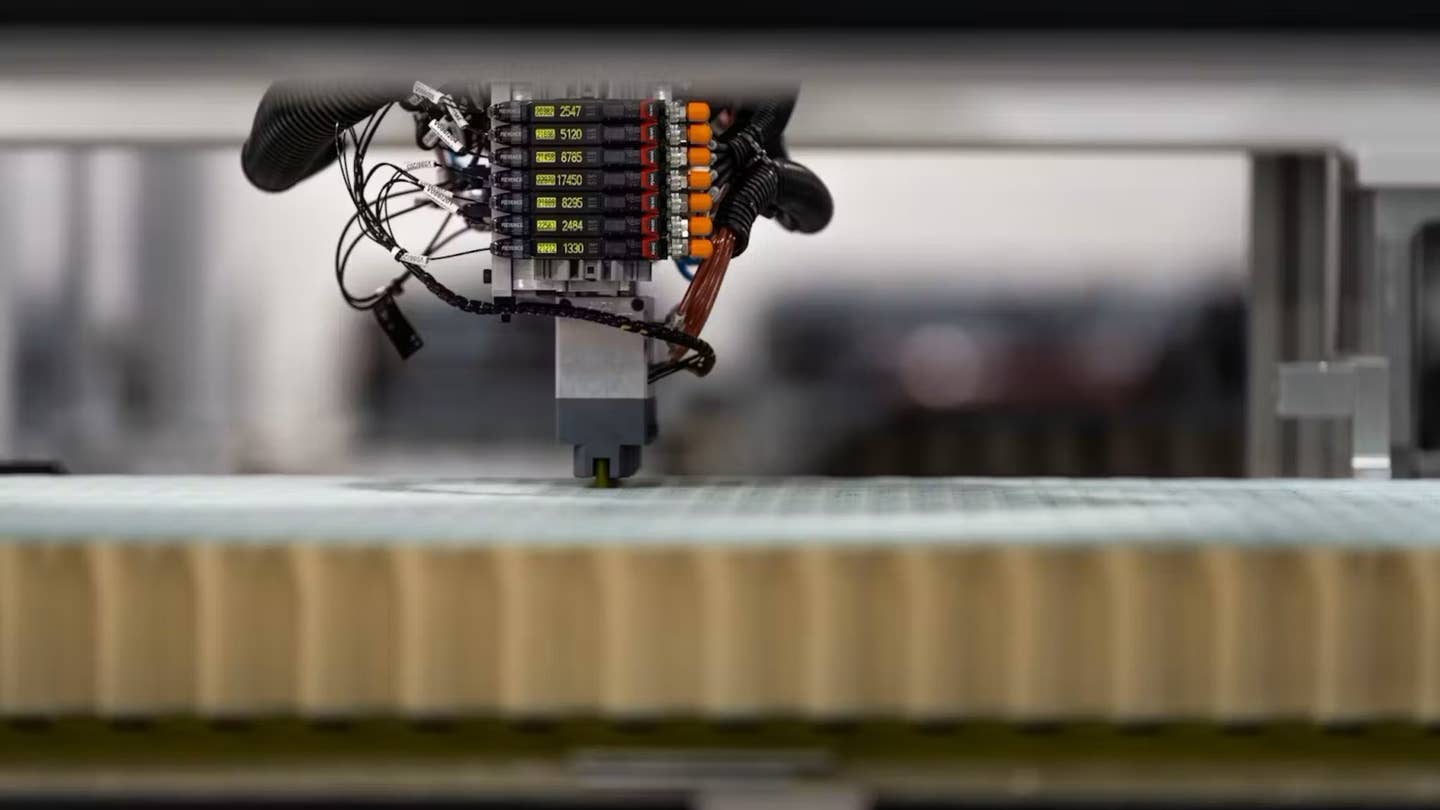

Archer’s high-volume battery pack production facility leverages automation for certain portions of the manufacturing process. [Courtesy: Archer Aviation]

Electric vertical takeoff and landing (eVTOL) aircraft manufacturer Archer Aviation is ready to produce thousands of lithium-ion battery packs for its flagship Midnight air taxi.

The manufacturer on Wednesday announced it completed the installation of an “automotive style” battery pack manufacturing line within its integrated test lab and manufacturing facilities in San Jose, California.

The production line is intended to complement the company’s air taxi manufacturing facility in Covington, Georgia, where it expects to initially produce up to 650 aircraft per year. The site remains under construction but is “on track” to be completed later this year, Archer reaffirmed Wednesday.

“This is a major milestone for Archer as designing, developing, and mass producing electric propulsion systems that are purpose built for electric aircraft is the key to unlocking the electrification of aviation,” said Tom Muniz, chief technology officer of Archer. “The facility will give us the capability to scale our battery pack production to meet the demands of the output that our Covington, Georgia, facility will be capable of.”

Each of Archer’s Midnight aircraft will run on six of the company’s proprietary lithium-ion battery packs, which power a dozen electric engines. The cylindrical cells within each pack deliver a higher level of safety, performance, and scalability than other form factors, Archer says. The packs are also equipped with a proprietary thermal runaway containment capability.

Archer’s new battery pack manufacturing line is designed to operate at full capacity from day one and, according to the company, is capable of producing up to 15,000 battery packs per year.

Certain portions of the manufacturing process—including cell testing and loading, adhesive dispensing, laser cleaning, laser welding, and end-of-line testing—have been automated. The manufacturer says this is intended to improve product quality and operator safety while making it easier to trace data across the manufacturing cycle.

Unlike the manufacturing strategy for the Midnight air taxi, which leverages outside suppliers to provide the majority of the aircraft’s components, Archer chose to vertically integrate battery cell design and production, building and assembling those components in house.

The battery packs in March successfully endured a series of 50-foot drop tests, a feat they will need to accomplish again during for-credit testing with the FAA. Similar to the 50-foot fuel tank drop test for rotorcraft and fixed-wing aircraft, the evaluation is meant to gauge the batteries’ ability to withstand a significant impact, which could cause a leak, fire, or explosion if the tech is not up to standard. Archer considers it to be one of the most challenging tests in the type-certification process for Midnight.

The manufacturer is also evaluating its battery pack technology with NASA via a Space Act agreement with the agency. Initial testing will gauge battery cell safety, energy, and power performance, studying how they might function in “extreme abuse cases.” The battery pack testing arrangement is just one portion of the agreement, Archer says.

Like this story? We think you'll also like the Future of FLYING newsletter sent every Thursday afternoon. Sign up now.

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox