The First Airworthiness Guide of the Maintainer Journey

FAA Advisory Circular AC 43.13 provides baseline knowledge pilots and technicians need to stay in compliance.

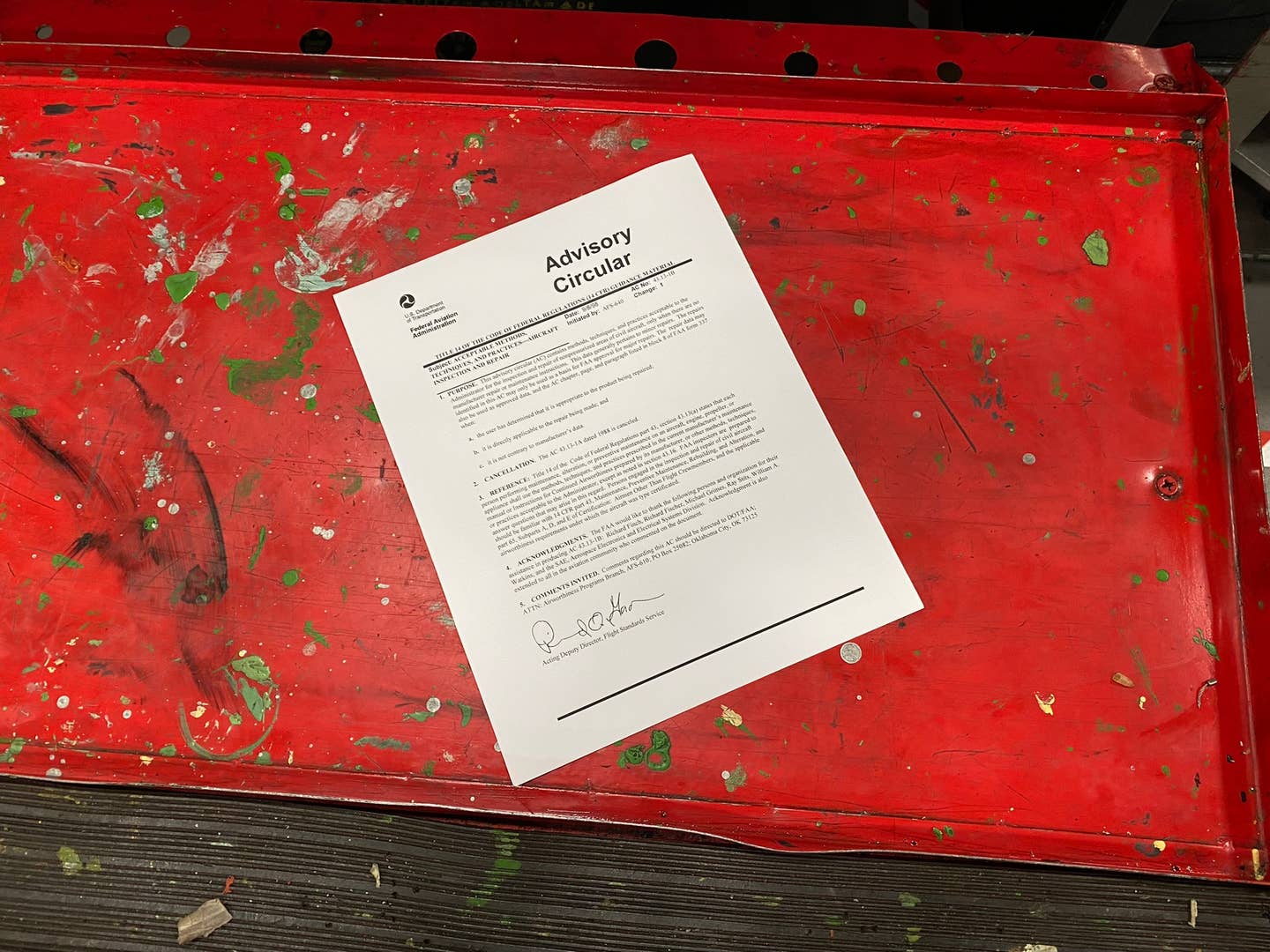

FAA Advisory Circular 43.13 is the first airworthiness guide many budding maintainers encounter when beginning their journey. [Photo: Richard Scarbrough]

Do you remember when you rushed down the hall in your socks and surveyed the wonders of what Santa deposited under the tree on Christmas morning? Those were magical times. Some of you may recall that I have a younger brother, David, and once during our teen years, we received matching Sears Craftsman toolboxes.

When younger, we received the standard gifts of the 1970s. GI Joe (the full-sized one that would cruise by a particular young lady's Malibu Dreamhouse on his way to liberate Stretch Armstrong), Mattel Hot Wheel cars, and the crown jewel of all gifts, Lego building blocks.

“These advisory circulars intend to give aircraft owners, operators, and maintainers a decent baseline to explore other manuals, procedures, and instructions. ”

Early on in our mutual builds, it was painfully evident what the outcome would be. One hour in and my brother had a car manufactured, a fully covered carport, and well on his way to a garage. On the other hand, I had a boss machine—a psychobilly battlewagon coupe, styled in the late Mad Max era.

What was the discerning factor that led up to this point? David read, analyzed, and followed the directions. My direction packet was still nicely tucked into the plastic sleeve from whence it came and remained there for longer than I care to admit.

Eventually, I followed the compliance path and began to build from the manual. It was fun completing each base, structure, or vehicle, and I had a knack for interpreting the pictures on the page and transforming the pile of pieces on our living floor into a tow truck.

Lego building blocks were a staple of our childhood play. As our skills improved, David and I came to rely on the manual less and less and soon created magnificent works of pre-teen engineering using only our imagination. Still, we always had the guidebook for reference when needed.

My first introduction to aviation technical publications (TechPubs) was at Naval Air Station (NAS) Millington during Aviation Maintenance, Structures (AMS) A School. These manuals were specific to my job rate and not applicable to our work together.

If you are reading this from an airbase or aircraft carrier, number one, thank you for your service, and two, shouldn't you be standing watch right now?

Entering airframe and powerplant (A&P) school began my journey into civil aviation. Our director, Jack Moore, drilled the importance of precision, integrity, and attention to detail and taught TechPubs early in the curriculum, our ground zero for maintaining anything aeronautical.

As we progress, you’ll learn each publication, the proper use, and how to access them. Today I want to introduce the FAA Advisory Circular 43.13, the first airworthiness guide many budding maintainers encounter when beginning their journey.

Published in two versions, the AC 43.13-1B covers acceptable methods, techniques, and practices of aircraft inspection and repair, and AC 43.13-2B guides proper processes, procedures, and practices of aircraft alterations. Together, these publications form the cornerstone of aviation maintenance.

For the followers of the old ways, Aircraft Spruce still carries the -1,-2 combined book version for purchase either online or at their brick and mortar locations.

There is a loose association between auto racing and aerospace. Those who depend on their equipment, maintain precision clearances, and cannot afford failure pay less attention to the procured entity and focus solely on the result. Here is a fun fact for you, Pegasus Auto Racing Supplies, Inc. sells copies of the AC 43.13 on its website.

Our instructors wanted us to have a firm footing in basic aviation maintenance techniques' concepts, practices, and applications by beginning with the basics. Most maintenance entities subscribe to a manual service that provides applicable TechPubs for their specific business. As the company grows in capabilities, the owners supplement their subscription with additional content, like picking up Beechcraft King Air work.

It is still highly beneficial to have a basic knowledge of aircraft structures, engines, systems, components, and avionics. It is important to note that original equipment manufacturer (OEM) guidelines take precedence when determining airworthiness. The AC documents can be used as references to bridge the gap when OEM manuals are unavailable.

An excerpt from AC 43.13-1B states the following:

This advisory circular (AC) contains methods, techniques, and practices acceptable to the Administrator for inspecting and repairing non-pressurized areas of civil aircraft only when there are no manufacturer repair or maintenance instructions. This data generally pertains to minor repairs. The repairs identified in this AC may only be used as a basis for FAA approval for major repairs. The repair data may also be used as approved data, and the AC chapter, page, and paragraph listed in block 8 of FAA form 337 when:

a. the user has determined that it is appropriate to the product being repaired;

b. it is directly applicable to the repair being made; and

c. it is not contrary to the manufacturer's data.

Chapter one begins with wooden structures. It is the most basic of all aircraft materials. The prominent building material until well into the 1930s, wood eventually passed the baton to lightweight corrosion resistant alloys like aluminum. Please note there are still many wooden airframes in service, and some use wood in new production kit aircraft like Fisher Flying Products and others.

The contents page demonstrates the subjects covered in the AC No: 43.13-1B.

Chapter 1. Wood Structure

Chapter 2. Fabric Covering

Chapter 3. Fiberglass and Plastics

Chapter 4. Metal Structure, Welding, and Brazing

Chapter 5. Nondestructive Inspection (NDI)

Chapter 6. Corrosion, Inspection, & Protection

Chapter 7. Aircraft Hardware, Control Cables, and Turnbuckles

Chapter 8. Engines, Fuel, Exhaust, and Propellers

Chapter 9. Aircraft Systems and Components

Chapter 10. Weight and Balance

Chapter 11. Aircraft Electrical Systems

Chapter 12. Aircraft Avionics Systems

Chapter 13. Human Factors

AC 43.13-2B deals with alterations and will get its article in the coming months.

The AC 43.13 publications are aircraft maintainers' versions of the Jedi sacred texts, holding the lessons, knowledge, and wisdom. For example, the cotter pin is the most basic aircraft hardware component. There cannot be a standard maintenance practice for installing a cotter pin. Really?

Cotter pins have to be aircraft-grade hardware for installation on certificated aircraft. They also must conform to standard installation practices before the mechanic can return the aircraft to service and release it to the wild. And how does one install a cotter pin? I am so glad you asked.

Page 7-26 of AC 43.13-1B, there is a description of a cotter pin installation procedure, and even gives two graphics, Figure 7-6 and Figure 7-7, respectively. I am sure it pains the FAA to say this, but there is a direct statement. I quote, "Cotter pins should not be reused on aircraft." I am confident that this explicit statement has ended more than one discussion between a mechanic and the value-driven aircraft owner.

If AC 43.13 emphasizes cotter pin installation, imagine the wonders that await you in the other chapters of this essential publication. Chapter 10 deals with weight and balance, 12 on avionics, and 13 deals with human factors—everything one would need to get started when maintaining their airplane.

The AC 43.13 documents should not be the authoritative voice on everything in aviation maintenance. They barely scratch the surface. These advisory circulars intend to give aircraft owners, operators, and maintainers a decent baseline to explore other manuals, procedures, and instructions.

Listen, I know you may never own a dope and fabric aircraft. Some have never even seen one. That’s OK. It doesn’t matter what you maintain and fly. Just do so in compliance. An excellent general baseline knowledge is all you need to get started.

Even though you have a Piper Cherokee, knowing the basics of covering a control surface with fabric is a life skill that will dazzle them at the local hangar hot dog fly-in. Perhaps you will even quiz your buddies on the proper placement of a bolt head or the number of twists per turn in safety wire.

I wanted to end this article with a picture of my original circa 1990 AC 43.13, dogeared and worn, with pages folded back, highlighted yellow, and scribbles galore. Sadly, it remained with my 145 Repair Station when I sold it. That's OK. In all honesty, I would rather see it still in service, answering questions, and guiding mechanics on the path of truth and righteousness, than sitting like a relic on my bookcase.

All right, here is your action item. Click the above links to each AC 43.13, bookmark or download them, and make it a point to look at least one question up a day for a month. You will find that one quest begets another, and before too long, you are settling disputes amongst your hangar mates. Also, you can finally toss all those old used cotter pins in the coffee can on your workbench. You won’t need them any longer.

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox